Lead acid battery

Are you looking for a CO2-free drive technology for your forklift? Then you are doing everything right with a lead-acid battery. The technology is particularly well suited for light to medium-heavy applications with low utilization. Heavy-duty applications are also possible with the help of a battery change. Depending on the intensity and duration of use, we offer a variety of different battery capacities. Our employees will be happy to assist you in choosing the right forklift battery.

Are you looking for a replacement battery? With our battery configurator you can quickly and easily find the right battery for any make of forklift.

Advantages of the lead-acid battery

Environmentally friendly technology without CO2 emissions

German quality product with good price-performance ratio

Batteries for all makes of forklift trucks

Waste battery disposal possible

Free delivery throughout Germany

Assembly included

Applications of lead-acid batteries

Lead-acid batteries are particularly suitable for areas with low utilization. This is the case for retailers, for example, as they only need the vehicle for a few hours a day for loading and unloading. In addition, e-trucks with lead-acid batteries can be optimally used indoors, as they do not emit any CO2.

For the use of forklift batteries in multi-shift operation, a battery change is usually necessary. Thanks to clever battery replacement systems (e.g. ROTABATT and BASICBATT), this can be carried out quickly and easily. It is also possible to order an integrated charger with the vehicle. Since the applications of the devices are very different, we also offer a variety of different battery capacities for the corresponding intensity and duration of use.

Structure & Function of Lead-Acid Batteries

When the battery is charged and discharged, the materials at the electrodes undergo a chemical reaction until they consist of lead sulfate at the positive and negative plates. The sulfuric acid provides the necessary sulfate ions.

During discharge, the acid density decreases. The state of charge can thus be determined via the concentration of sulfuric acid in the electrolyte. During charging, the processes run in the opposite direction. There is then a loss of water, as the resulting acid and hydrogen escape upwards.

The battery level must therefore be checked regularly and distilled water topped up after charging.

More efficiency thanks to matching accessories

A water refill system, electrolyte circulation and the right charger can significantly increase the efficiency of lead batteries. Our experts will be happy to help you find the right accessories for your battery.

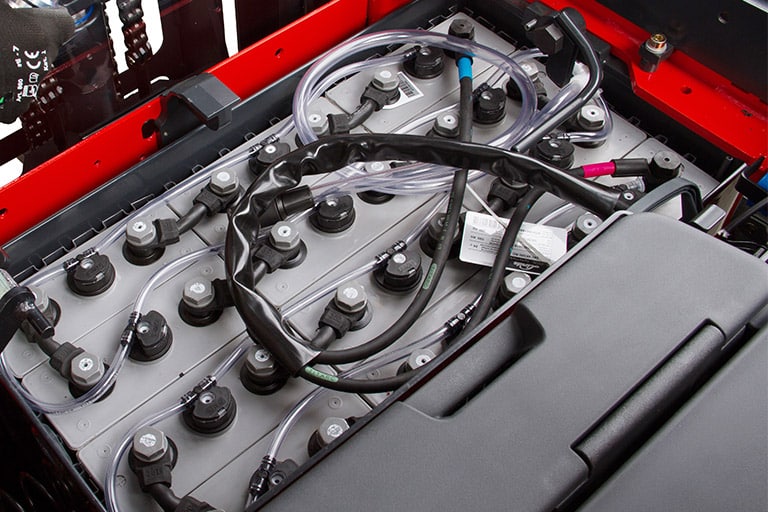

Aquamatik" water refill system

During the charging process, a lead-acid battery consumes battery water. To compensate for this loss, the battery must be regularly refilled with distilled water. With our water refilling system , the cells can be filled centrally via a hose system.

Electrolyte circulation (EUW)

In electrolyte circulation (EUW), an air flow is directed into the cell via a diaphragm pump to achieve better circulation of the liquid electrolyte. This eliminates acid stratification and optimizes charge absorption. This enables shorter charging times and longer battery life.

Chargers

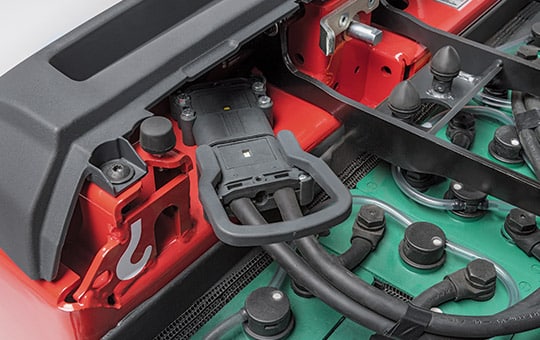

Regardless of whether you need an integrated or external charger for your lead-acid batteries, GRUMA offers a wide range of devices with different power ratings. We will be happy to find the most economical and efficient solution for you, taking into account your conditions on site.

Battery change made easy

BASICBATT 48 V battery replacement system

The BASICBATT battery changing system is perfect for all 48 volt batteries with 4 PzS, 5 PzS and 6 PzS.

Battery changing system ROTABATT 80 V

The ROTABATT battery changing system is suitable for all 80 volt batteries with 4 PzS, 5 PzS and 6 PzS.

Battery handling

This will ensure a long life for your lead-acid battery.

How to charge a lead-acid battery?

Proper charging has an enormous influence on the service life of a forklift battery. Therefore, always observe the following rules:

- Do not fall below nominal capacity of 20%

- Always fully charge the forklift battery: Never leave battery in discharged state for a long time

- Avoid charging with excessive currents: Use permissible charger with direct current

- Open or remove the trough lid during charging so that battery gases can escape

- Connect the battery with the correct polarity to the charger when it is switched off.

Care tips for lead-acid batteries

- Check the amount of electrolyte after each charging process

- Check electrolyte concentration every two months

- Wear suitable protective clothing when refilling electrolyte

- After 5 - 10 charging processes, top up battery water to the mark (distilled or demineralized).

- Periodically wipe off dust, dirt from the surfaces

- Check battery regularly for mechanical damage and leaking electrolyte

Frequently asked questions

We will gladly take over the disposal of your used batteries. Simply contact our employees for this purpose. They will also be happy to advise you on a suitable replacement battery.

To avoid damage when starting up an acid battery after a long period of non-use, you should observe the following points:

- Fully charge the battery if you do not plan to use it for a long time.

- Then check the filling level of the battery. Add distilled water if necessary.

- Even when the battery is not in use, fully charge it at least every 3 months.

- Always keep the surface of the battery clean and dry.

To avoid hazards when charging lead-acid batteries, basic safety requirements should be observed when planning, installing and operating battery charging systems (charging rooms, charging stations, individual charging stations).

Lithium-ion batteries have the same external dimensions and weight as lead-acid batteries. This is done to ensure the stability of the vehicles. Both systems have different capacities with corresponding price gradations. In contrast to lead-acid batteries, lithium-ion batteries are maintenance-free and do not produce any gases. In addition, they have a 3-5 times longer service life and can be flexibly recharged within a very short time.

Do you still have questions?

David

Sieverdingbeck

Maintenance for forklift batteries

Maintenance procedure:

- 0:05 Cleaning the forklift battery

- 0:13 Drying the battery surface after cleaning

- 0:18 Suctioning off the exposed electrolyte (sulfuric acid)

- 0:38 Extracted electrolyte is immediately transferred to suitable containers and disposed of properly

- 0:50 Defective / oxidized components of the forklift battery (EUW and BFS) are replaced on site.

- 1:09 Comparison: defective components with new components

- 1:15 Sustainable maintenance

- 1:20 Function and leak test on the forklift battery (BFS and EUW system). Battery fluid is topped up.

You might also be interested in

- Spoilt for choice: At GRUMA, you can obtain a wide range of different chargers with different power ratings.

- Environmentally friendly, energy-saving and refuelled in 3 minutes - fuel cells are THE drive of the future. Learn all about the advantages now.

- Environmentally friendly, efficient and safe work with high vehicle availability and cost-effectiveness - even in multi-shift operation? Our innovative lithium-ion batteries make it possible.

- Whether lead-acid battery, lithium-ion battery, fuel cell, diesel or propellant gas. Our energy experts will help you find the right energy system for your operation.