Chargers for forklift

At GRUMA, you can obtain a wide range of different chargers for forklift batteries with a wide variety of performance levels. Choose between chargers for lead-acid batteries or chargers for lithium-ion batteries.

- Chargers for lead-acid batteries

- Chargers for lithium-ion batteries

- Personal advice

Innovative charging technology for your traction batteries

Due to the powerful technology of electric forklifts, more and more operators are now switching to electrically powered industrial trucks. In addition to industrial trucks that are optimally matched to the application and the correctly selected forklift batteries, the charger is another important factor for efficient use. All this has to be seen in the light of the highest availability and the highest handling performance. Even when using only one vehicle, it is important to coordinate the various components. Only in this way can you be sure of operating an industrial truck at the lowest possible cost.

With a perfectly matched battery and charger concept, you optimize your ongoing operating costs and ensure smooth (multi-shift) operation.

The availability of the overall system consisting of vehicle - battery - charger is always in the foreground. The selection of the right charger for each application is crucial here. The decisive factors here are the respective operating conditions, the available charging time, as well as the battery technology used and the selected battery capacity.

Battery charging systems for industrial trucks

What is a battery charger and why do I need it?

A battery charging facility includes charging rooms, charging stations, single charging places as well as all electrical equipment necessary for charging a battery. So it is a room or place where the forklift batteries are charged.

There are different versions here, depending on the size of the forklift fleet. In the case of a battery charging room and a charging station, the forklift batteries are removed from the industrial truck for the charging process. These versions are very useful in multi-shift operation, for example. With a single charging bay or charging station, the battery remains in the truck during the complete charging process.

Fleet operators will have to deal with this topic much more intensively in the future when it comes to charging technology. GRUMA supports you in the selection and placement of the chargers, taking into account the existing regulations. Even more demanding is the planning of a separate battery charging room with individual charging stations. In this case, it is necessary to involve a specialist already during the conceptual planning of a new building or a conversion.

We offer you the know-how and can work out a ready plan for you.

Various charging options for forklift batteries

Battery charging room

The battery charging room is a space where forklift batteries are temporarily placed for charging. The chargers are physically separated from forklift batteries.

Battery charging station

Forklift batteries can be temporarily connected to the battery charging station for charging. The chargers are here in the same room with the forklift batteries.

Single loading bay (loading point)

A single charging bay is a bay that is specifically equipped for charging forklift batteries through the appropriate layout and signage.

What do I need to consider when setting up and using battery systems?

When using electric forklifts, every company needs a battery charging system, i.e. a defined space or room in which one or more chargers can be set up. Not all areas in a company are suitable for this. Experience shows that there are still many companies that do not think through the selection of a suitable place enough and do not consider the basic safety requirements for such a place.

Through a risk assessment, you can analyze which measures are necessary for your company. Our specialists will be happy to support you in this endeavor.

What are the minimum distances that must be maintained for battery installations?

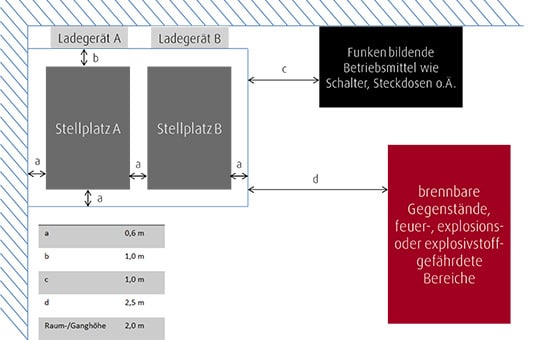

There should be a distance of at least 0.6 m between the individual positions. Chargers and spark-generating equipment, such as switches, sockets or similar, should be positioned at least 1.0 m away. A distance of at least 2.5 m is required from flammable objects, areas subject to fire, explosion or explosive hazards. The room/aisle height should be at least 2.0 m.

You might also be interested in

- Environmentally friendly, energy-saving and refuelled in 3 minutes - fuel cells are THE drive of the future. Learn all about the advantages now.

- Proven technology with a good price-performance ratio - that's what lead-acid batteries stand for. The ideal energy storage for forklifts with high energy and cycle applications.

- Environmentally friendly, efficient and safe work with high vehicle availability and cost-effectiveness - even in multi-shift operation? Our innovative lithium-ion batteries make it possible.

- Whether lead-acid battery, lithium-ion battery, fuel cell, diesel or propellant gas. Our energy experts will help you find the right energy system for your operation.