Automation of logistics processes

Do you want full marks for your goods handling? Then you should think about automating your logistics processes with automated guided vehicles (AGVs). This is particularly worthwhile for load handling processes with low added value, long distances and repetitive processes. But the systems can also be used profitably in multi-shift operations and with largely standardized load carriers.

Our driverless transport vehicles (AGVs) are a central component of our integrated solutions. They increase productivity and transport quality and reduce the risk of accidents. In addition, the use of these vehicles promises greater transparency in the analysis and optimization of internal processes.

Would you like to make your processes more efficient and intelligent? Our experts will be happy to work with you to develop your personal automation concept.

Good reasons for FTS

Reduction of accidents with damage to persons or infrastructure

Increase in productivity, capacity utilization and transport quality

More order, safety and reliability

Fast, smooth system integration possible

Switch between manual and automatic travel mode possible

Solutions are flexibly expandable and adaptable

Your process - Our solution

The automation of logistics processes does not always have to mean a major project. With our standardized solution packages, even individual, constantly recurring process steps can be easily automated. Our offer includes suitable devices from the Linde MATIC series, the corresponding software and on-site commissioning.

Download process checklist now

Process checklist automation

On the way to the autonomous outdoor forklift truck

An autonomous forklift truck outdoors? This is no longer fiction. As part of the "KAnIS" research project by Linde MH and the TH Aschaffenburg, innovative autonomous counterbalanced trucks have been developed that use advanced sensor and AI technologies. The new trucks ensure safe operation in various environments and include innovations such as a sensor cleaning system and an AI-controlled system for autonomous loading.

Rent automated vehicles

You are unsure whether an automated vehicle fits into your operation? We would be happy to offer you the opportunity to test or rent an automated vehicle for a longer period of time. Simply get in touch with your contact person.

Automated solutions from Linde

Driverless transport

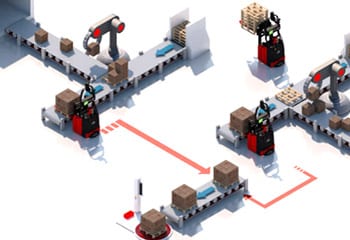

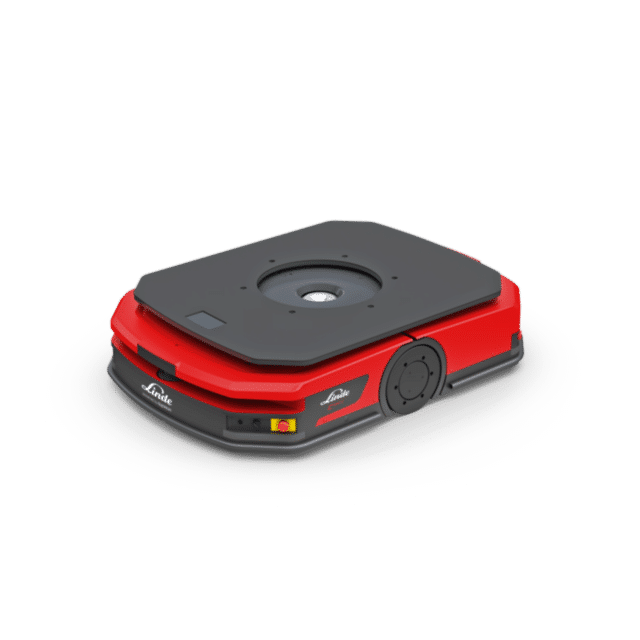

Standardized process sequences in which goods have to be transported over short or medium-length distances to precisely defined positions are part of everyday logistics. Autonomous Mobile Robots (AMR), such as the self-propelled platform truck C-MATIC, are ideally suited for automated or partially automated material transport and significantly increase the efficiency of these processes. The load can be picked up and set down together with under-ride transport tables or optionally with pallets. In addition, transport between static transfer stations or conveyor belts is possible. Obstacles in the route are detected by both the C-MATIC and the C-MATIC HP, and the latter also independently avoids them. Depending on the model, the automated vehicle can handle loads of up to 600, 1,000 or 1,500 kilograms.

Loads up to 1,500 kg

Speed up to 7.2 km/h

For short or medium length routes

Advantages of AMR vehicles

- Compact and maneuverable

- Transport of different load carriers

- Effortless integration into existing processes

- Fully automated charging of the battery

- Use of maintenance-free lithium-ion technology

- Navigation and load tracking is done via QR codes

- Optimal route guidance and assignment of driving jobs

Areas of application

The C-Matic can show its strengths particularly in the transport of goods between workplaces(order picking) and transfer stations(line transport).

There, the driverless transport system can be used to transport individual load carriers, multi-level load area, conveyor trolleys or trolleys for different dimensions of the load carrier and different transfer heights.

Implementation

Depending on the model, AMR use different technologies for navigation.

The C-MATIC uses lane-guided navigation via QR codes. In this process, the autonomous platform truck orients itself using QR codes on the ground. This allows routes for transport orders to be flexibly adapted and calculated.

The C-MATIC HP, on the other hand, uses laser-based contour navigation, also known as GEO navigation.

We will be happy to advise you on the two technologies and help you make your choice.

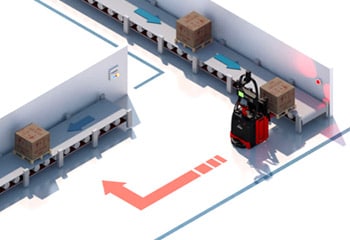

Loading and unloading

The L-MATIC automated high lift trucks from Linde Material Handling are perfect for storing or retrieving goods at low and medium heights up to 4.14 meters. The automated reach truck R-MATIC is the perfect all-rounder for wide aisle warehouses with storage up to 11 meters.

Loads up to 2,000 kg

Speed up to 7.3 km/h

Standard lifting heights up to 11 meters and aisle widths starting at 3 meters

The most important features at a glance

- Innovative GEO navigation

- No structural measures necessary

- Fast and easy integration into existing processes

- Simple and fast extension of the recording processes and delivery points

- Dual mode: manual and automatic use

- Low maintenance due to the use of standard devices

- Real time localization of the robots

Special customer solutions

- RFiD Scanner | Automatic identification of RFiD tags

- Barcode scanner | Automatic identification of the goods

- ERP interface | Connections to existing ERP systems

- Forklift call system | Easy transport assignment of automated equipment

- High-performance batteries | High-performance batteries with quick-charge function for full charges in 15 minutes

- Automated loading process | Completely automated loading process without manual intervention

- Daily Reporting | Daily automatically generated statistics

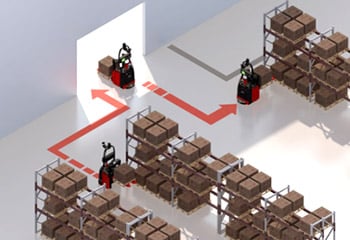

Driverless picking

The autonomous K-MATIC high-rack stackers are designed for loads of up to 1,500 kilograms and lift heights of up to 13 meters. Intelligent GEO navigation safely controls the K-MATIC without additional tracks in the floor or laser reflectors in all common narrow aisle applications.

Loads up to 1,500 kg

Speed up to 9 km/h

Standard lifting heights up to 13 meters and aisle widths from 1.8 meters

The most important features at a glance

- Innovative GEO navigation

- No structural measures

- Fast and easy integration into existing processes

- Simple and fast extension of the recording processes and delivery points

- Dual mode: manual and automatic use

- Low maintenance due to the use of standard devices

- Real time localization of the robots

Special customer solutions

- RFiD Scanner | Automatic identification of RFiD tags

- Barcode scanner | Automatic identification of the goods

- ERP interface | Connections to existing ERP systems

- Forklift call system | Easy transport assignment of automated equipment

- High-performance batteries | High-performance batteries with quick-charge function for full charges in 15 minutes

- Automated loading process | Completely automated loading process without manual intervention

- Daily Reporting | Daily automatically generated statistics

Driverless logistics trains

From small parts storage to complete assembly lines: Linde Material Handling offers you automated tow tractors for line transport of up to 1,000 meters. As with other MATIC models, manual and automated operation of the vehicles is possible. To ensure a hazard-free workflow, the machines also meet the highest safety requirements.

Up to 5,000 kg tractive force

Combinable processes (manual / automatic)

Different trailer solutions, automatic trailer hitch

Advantages of automated tugger trains

- Continuous, clocked material supply

- Small aisle widths, space saving

- Less crossing and oncoming traffic / reduced risk of accidents

- Fewer empty runs

- Automated and manual operation possible

- Customized trailer design

- Quick and easy installation without changing the workstation layout

- Linking to the existing TRP system

Special customer solutions

- RFiD Scanner | Automatic identification of RFiD tags

- Barcode scanner | Automatic identification of the goods

- ERP interface | Connections to existing ERP systems

- Forklift call system | Easy transport assignment of automated equipment

- High-performance batteries | High-performance batteries with quick-charge function for full charges in 15 minutes

- Automated loading process | Completely automated loading process without manual intervention

- Daily Reporting | Daily automatically generated statistics

The right software for your automated guided vehicle systems

Linde Truck Call

With Linde Truck Call, you can effortlessly control your logistics orders via an app on your smartphone or tablet. This simplifies the assignment of driving jobs within the fleet and shortens the communication path between shift managers and drivers.

Linde Warehouse Manager

The Linde Warehouse Manager is a lean, low-cost warehouse management system (WMS) that is ideally suited for entry into digital warehouse management. The system can be used to manage all warehouse processes without much effort: from goods receipt to storage to goods issue.

Linde Warehouse Navigator

The term Linde Warehouse Navigator refers to a forklift guidance system that specializes in warehouse processes in large block storage facilities. The system automatically identifies goods and pallets, so that it is always known where a forklift is currently located and which goods it is transporting. It thus ensures efficient material flows and reliable goods tracking.

Linde VNA Navigation Interface

As a supplement to Linde warehouse navigation, the Linde VNA Navigation Interface enables communication between the vehicle's warehouse navigation and the Warehouse Management System. The advantage: the destination coordinates for the next transport order are no longer entered by hand, but are fed directly into the vehicle's navigation software.

Frequently asked questions

Automated guided vehicles (AGVs) are part of the automation in the logistics process. They are floor-based conveyor systems with automatically controlled vehicles for transporting materials and goods. AGVs are subject to constant location determination and data transmission, among other things for orientation in space and control. The series vehicles from Linde Material Handling are used and optimized accordingly for the new requirement. With GRUMA's automated vehicles, you are always flexible and can react quickly even to situations that change at short notice. The investment for autonomous transport systems has paid off for you within a very short time.

To enable our driverless industrial trucks to move quickly and safely through the warehouse, we rely on GEO navigation (also: contour navigation) for our Linde MATIC vehicles.

In the first step, the surrounding infrastructure is recorded with the help of a digital mapping. The map is then cleansed of disruptive factors and individual routes and transport paths can be defined and adapted.

The driverless transport vehicles are then controlled by a laser-based navigation system that scans its surroundings in all directions using laser sensors. They compare the corresponding parameters on their transport journeys with the previously recorded "digital" map in order to navigate the existing infrastructure without any other aids.

Intelligent control software coordinates the routes and speed of the geonavigated AGVs among themselves. The advantage of the technology clearly lies in its flexibility, as it can be easily adapted to new routes and environments.

With our driverless transport systems, there is the option of operating them autonomously or manually if required. This switch is possible because the autonomous forklifts, tow tractors and lift trucks are based on manual equipment that has been subsequently automated. To enable hazard-free mixed operation, the driverless transport vehicles of the MATIC series feature intelligent navigation and safety technology.

Any company that performs consistent and uniform logistics processes with material handling equipment on a daily basis should consider automated processes in their operations. Especially for long distances, repetitive processes, multi-shift operations and processes with low added value. If you are looking to optimize your flow of goods in terms of cost, safety and error reduction, it definitely makes sense to consider automating your warehouse.

Our Linde MATIC range includes many different vehicle types. These include automated tow tractors, high lift trucks, reach trucks, platform trucks and narrow aisle trucks. The choice of the right AGV depends on the task or process to be automated. We will be happy to support you in your selection.

No system, machine or person can work 100% fail-safe. However, all our AGVs are optimized in the best possible way and can also be operated manually (dual) if necessary, which is a great advantage for the development of an "emergency concept". We would be happy to work out a joint concept with you to ensure the greatest possible planning reliability for you. If there is a problem with the unit, GRUMA Service will of course be at your site quickly. However, due to regular maintenance and safety measures in the system, failures are not a frequent problem.

FTF = Driverless transport vehicle

AGV = Automated Guided Vehicle

AMR = Autonomous Mobile Robots

Our product range for download

GRUMA performance overview

You might also be interested in

- Whether lead-acid battery, lithium-ion battery, fuel cell, diesel or propellant gas. Our energy experts will help you find the right energy system for your operation.

- In times of Industry 4.0, fast workflows are essential. Here it is advisable to rethink process flows in the company and automate them as far as possible.

- Discover the savings potential in your intralogistics processes. With the right fleet management, you can structure and optimize your flow of goods.

- Manage all vehicle and driver data in one place? The Linde connect fleet management system can do that and much more. Discover functions now!