Forklift repair and maintenance

Industrial trucks must be available at all times. GRUMA helps here with services for maintenance and repair / overhaul. Our highly qualified service technicians ensure compliance with service intervals and carry out maintenance and repairs quickly and reliably.

Regular maintenance reduces operating costs and increases the resale value of the industrial trucks. In addition, consequential damage is detected at an early stage, which may prevent expensive repairs.

Repair of forklift trucks and warehouse equipment

Forklifts are heavily stressed work equipment. Extreme environmental influences, such as in foundries, cold stores, the fishing industry or industries with high dust loads, can additionally accelerate wear.

In the event of damage, we help immediately. A service technician will make his way to you with spare parts.

Maintenance of forklift trucks and warehouse equipment

Southern Germany's largest team of forklift service technicians is on the road for you - each with a comprehensively equipped service vehicle, complete with diagnostic laptop and test equipment.

GRUMA measures customer service response time not in days but in hours, which in a territorial state like Bavaria means "Tempo, Tempo". There are 15,000 customers to be served with a total inventory of around 35,000 vehicles.

Good reasons for the GRUMA repair & maintenance service

Greatest possible cost security in the event of a warranty claim

High level of know-how through well-trained service technicians

Avoidance of expensive consequential damage through early detection

Operational safety for your driving personnel

The basis for carrying out maintenance and repairs is the manufacturer's operating instructions

Excerpt from the operating instructions:

"Your forklift will only remain in operational condition at all times if the few inspection and maintenance tasks are carried out regularly in accordance with the information in the operating instructions. Maintenance may only be carried out by qualified persons authorized by the manufacturer."

Repair & Maintenance Frequently Asked Questions

The forklift is not only constantly exposed to a wide variety of environmental influences and loads, but also to natural wear and tear through daily operation (comparable to a car).

When you buy a Linde forklift truck, you are not only opting for maximum efficiency, innovation and driving comfort, but also for perfect service and comprehensive support. Because no one knows your truck like we do - the Linde Material Handling professionals. Countless hours of training by our service technicians, optimally equipped service vehicles and know-how in organization guarantee your truck a long and worry-free service life.

The scope of maintenance differs according to type and series and according to the number of operating hours.

The number of maintenance operations required therefore depends to a large extent on the number of operating hours. From a few hours per week to continuous operation around the clock. You can find out which maintenance interval is due when from the operating manual or it is conveniently shown on the display of your truck.

Forklift maintenance - Services at GRUMA

Inspection of the forklift tire

We check the suitability of your tire and ensure a quick change if necessary.

Lubrication of the steering axle

For safe steering, we check and lubricate the steering axle on your forklift.

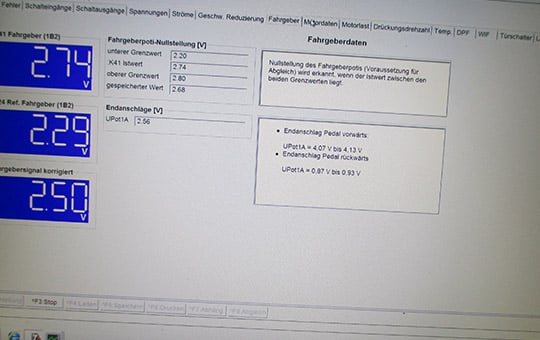

Reading out the error memory

We read the error memory of your truck and calibrate it correctly.

Testing forklift batteries

We subject your forklift battery to a detailed visual inspection and clean it in the process.

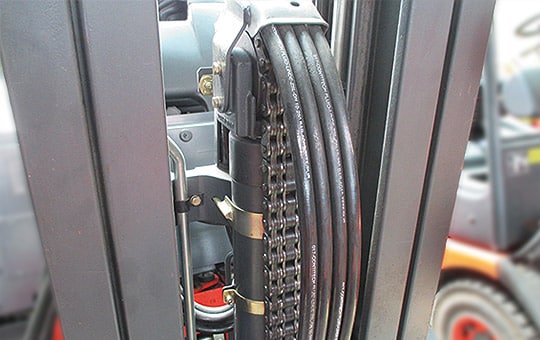

Checking cables and hoses

We check cables and hoses and replace them if necessary.

Oil level check

An oil level that is too low or too high can damage the engine of the forklift. We check the quantity and top up if necessary.

Checking the toothed belt

Just like in a car, the timing belt is a common wearing part in a forklift truck. We check it and replace it if necessary.

Checking the coolant

The coolant of a forklift truck should also be optimally filled at all times. We change or refill this as needed.

Checking the hydraulic oil

The hydraulic oil is an important component in the forklift. We check the level of the hydraulic oil and change it if necessary.

Cabin Filter Cleaning & Change

We will clean a dirty cabin or pollen filter and replace it if it is too worn.

Function test soot particle filter

Especially in closed rooms, the function test of the soot particle filter is enormously important.

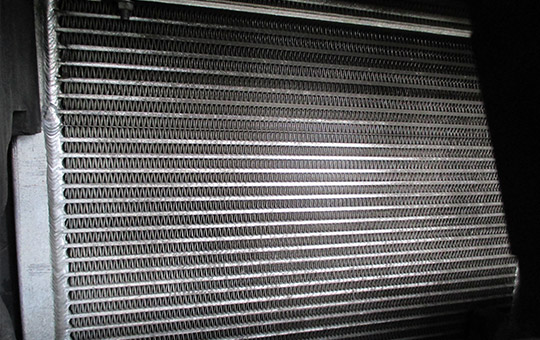

Forklift radiator inspection

We check the radiator of the forklift and blow it out if necessary.

Filter change on forklift

The forklift filter is also maintained and replaced as needed.

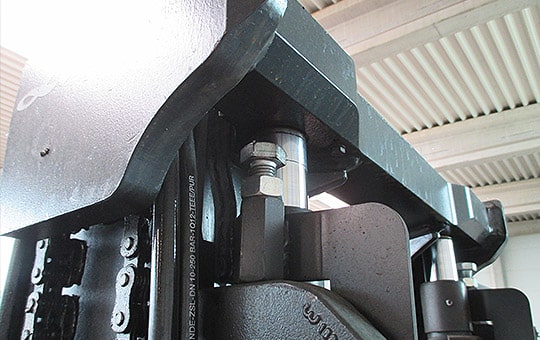

Setting the lowering limit

Our technicians can also perform the setting of the lowering limit.

Checking hoses, chains and load rollers

We also routinely perform this check for you.

Attachment lubrication

We lubricate the attachment attached to your forklift at the critical points for you.

Checking the pedal pads

Pedals lose grip over time and are therefore checked by us, cleaned and replaced if necessary.

Function control of the lighting

A damaged or defective lighting device will also be replaced by our technicians.

Control unit lift mast

Our tests determine whether the operating unit of the forklift truck, which is always in use, functions correctly.

Reset interval and function test

We perform various functional tests on the forklift for you.

Maintenance for forklift batteries

After the legally required inspection of forklift batteries, we also take over the maintenance of your batteries. During the maintenance of forklift batteries, the full function of the batteries is ensured or restored.

- 0:05 - Cleaning the forklift battery

- 0:13 - Drying the battery surface after cleaning

- 0:18 - Suction of the exposed electrolyte (sulfuric acid).

- 0:38 - Extracted electrolyte is immediately transferred to suitable containers and disposed of properly

- 0:50 - Defective / oxidized components of the forklift battery (EUW and BFS) are replaced on site.

- 1:09 - Comparison: defective components with new components

- 1:15 - Sustainable maintenance

- 1:20 - Function and leak test on the forklift battery (BFS and EUW system). Battery fluid is filled up.

Forklift emergency service: For urgent problems

For urgent emergencies outside our normal business hours (including public holidays), our emergency service will be happy to assist you.

Emergency service number Derching: 0821 / 780 00 - 33 40

Emergency service number Garching: 089 / 32 93 99 - 992

If you request information by telephone or a service technician for an emergency service call outside our business hours, a flat rate of €203.50 will be charged, as well as the working hours and travel costs incurred (at cost).

In addition, overtime pay will be added as follows:

Mo. - Fr.: from 07:00 to 17:00 0 %

Mo. - Fr.: from 17:00 to 19:00 25 %

Mo. - Fr.: from 19:00 to 07:00 50 %

Saturday 50 %

Sunday and holiday 100 %

You might also be interested in

- You need a forklift or lift truck that is not off the shelf? Our special construction specialists will customize your vehicle according to your wishes.

- From changing forklift tires to disposing of used tires - the GRUMA forklift tire service is there for you throughout.

- Nothing remains undetected! We will gladly carry out the legal inspection of your forklift trucks and warehouse technology carefully and advise you competently.

- Do you need service for forklifts or agricultural machinery? Whether maintenance, repair, testing or tire service - in our vast service network you are well taken care of.

Are you interested in our service offers?

Here you can make a non-binding request. Please leave us a message. We will get back to you immediately.