An ergonomically designed workplace plays a key role in enabling a forklift operator to fully exploit his performance potential. Conversely, more ergonomics on the part of the operator leads to higher handling performance for the company. Accordingly, the goal for every company should be a maximally optimized ergonomic workplace. Steering plays a central role in the operation of a forklift truck. But how can it be made even more ergonomic? The handling specialist Linde Material Handling (MH) has now presented a promising solution at the World of Material Handling (WoMH) customer event.

Driving a forklift without a steering wheel - this is how it works

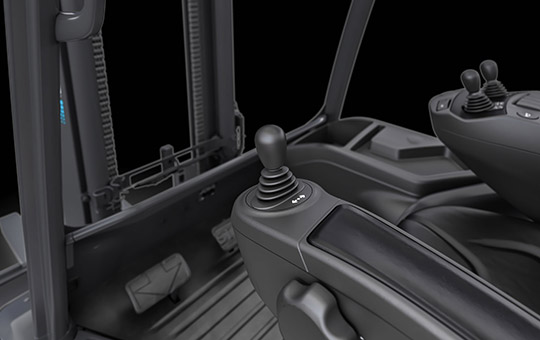

At the "Linde Steer Control"is a new type of electrohydraulic steering system that does not require a conventional steering wheel. The driver's arm rests on the armrest. The truck is steered either by an integrated mini-wheel or a joystick operated by the left hand. This makes working in the forklift more relaxed and the operator consequently remains concentrated and efficient for longer. Looking to the future, this fulfills another important requirement for the automated counterbalanced truck.

Precise, safe control

Linde Steer Control is based on steer-by-wire technology. Here, the driver's control commands are converted into electrical signals and forwarded to the hydraulic actuators. A sophisticated safety concept guarantees the fail-safe operation of the vehicle control system.

The electric control of the wheels also opens up new functional possibilities. For example, even more precise control of the truck is possible, as the steering reacts more or less sensitively depending on the vehicle speed. If the operator wants to drive faster, then the mini-wheel must be turned more or the joystick tilted further to the side to cause a certain steering deflection of the wheels. If the speed of the forklift is reduced, the same hand movement results in a stronger steering deflection.

Linde MH recommends the Mini-Wheel for classic everyday tasks, such as line transport, maneuvering or storage and retrieval processes. Because of the analogy to the steering wheel, a particularly steep learning curve can be expected there.

The joystick, on the other hand, has another special feature that could have a positive effect in certain applications. As soon as the driver releases the control, the steering wheels automatically turn to the straight-ahead position. This function proves to be extremely helpful in block storage facilities with long, narrow a isles.

Study confirms advantages of the steerless truck

In order to be able to evaluate the ergonomic benefits of Linde Steer Control, Linde MH conducted a user study together with RWTH Aachen University and fka GmbH in spring 2022. The study addressed the question of the extent to which the new steering concepts reduce the driver's body movements and lead to less strain on the arm and shoulder. The study participants, aged between 19 and 67, had held their forklift driver's license for at least three years at the time of the study. They also had sufficient driving experience, as they used the forklift on a daily basis due to their profession. A special camera was used to record the range of motion of the shoulder, elbow and wrist, which was then analyzed. The result of the study: Both the mini-wheel and the joystick cause less joint movement in the shoulder and elbow compared to the conventional steering wheel.