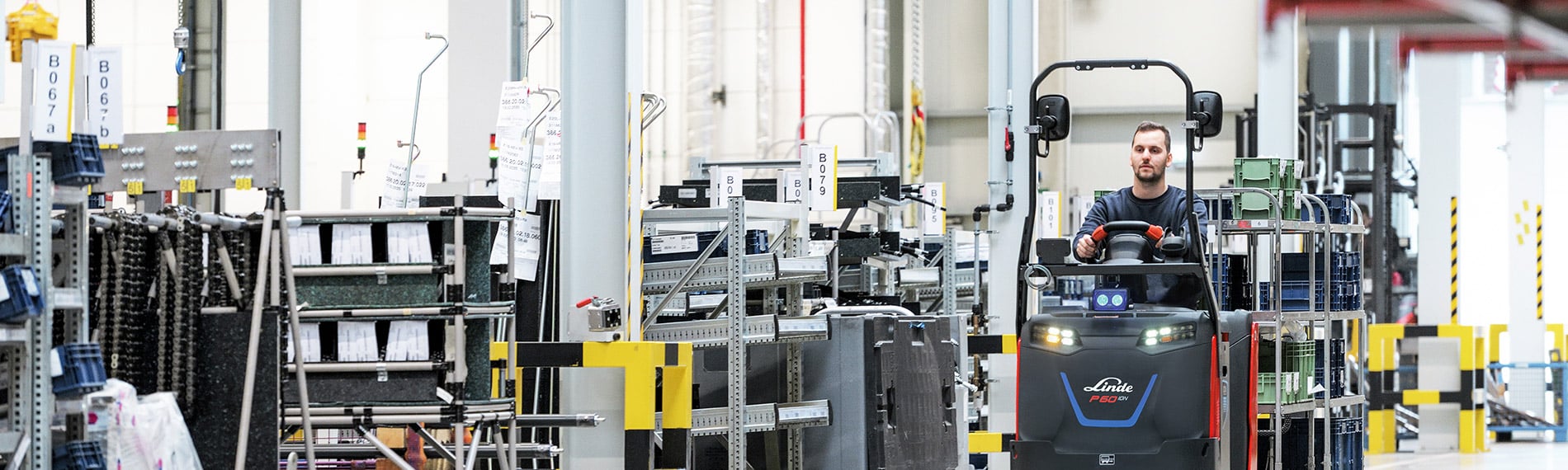

Road trains | Logistics trains

With the tugger trains from Linde Material Handling, clocked material transports over longer distances in the company can be organized efficiently and flexibly. With their tractors, they combine different trailer modules for transport distances from 150 meters. They can be loaded with up to 3,000 kilograms per trailer module.

Safety for personnel and materials is a top priority. The trailer modules are suitable for all conceivable loads and transport goods - from pallets to mesh baskets to individual items. All route or logistics train models also feature high tipping stability, directional stability and tight turning circles.

Advantages of Linde's route or logistics trains

Economical use already from 150 meters

Convenient charging and discharging

Up to 3,000 kilograms per trailer module

Time-saving mass transport instead of individual transport

Good reasons for route or logistics trains from Linde

Even if the keyword "handling efficiency" may sound a little trite, it very aptly describes the central advantages of Linde's tugger trains and logistics trains. Thanks to the flexibility with which the trailer modules can be adapted to almost all transport goods in the company and their minimal turning circle for operations even in the smallest spaces, hardly any wishes remain unfulfilled for complex requirements. Linde's logistics trailers work with versatile loading frames, some with lockable trolleys for the goods to be transported, which are raised by a lifting mechanism for transport and lowered again for unloading. This saves time, is convenient and therefore effective.

Modular, freely combinable trailers

No matter what your requirements are, there are freely combinable trailers for almost all goods or container dimensions that typically exist in the company. These can be loaded with different roll frames and are available for outdoor as well as indoor applications.

Ergonomic and safe

Linde is known for logical safety features such as the start-up interlock. It ensures, for example, that the train cannot start moving unless all load frames are raised. Driving assistance systems for the train tractors throttle the speed in curves and, of course, all trailer modules of the Linde route or logistics trains are connected to the tractor by data cable.

This allows the operator to centrally operate the lifting function of all trailers from the driver's cab. He always has a full overview of all load frames. However, they can also be operated individually on the respective trailer conveniently by foot sensor. Incidentally, the lifting function is deactivated during the journey and the load is monitored electronically. Dangers are thus actively avoided.

Precise, simple and future-proof

Without exception, the trailers are each equipped with four steerable wheels - making precise handling child's play. Particularly in tight spaces and between production lines, maneuvering with four trailers is hardly more strenuous. The wheels, optionally available as spring-mounted variants, are attached to elaborate tilt axles. This guarantees absolutely gentle transport of the loads. Trailers with bridge frames allow loading and unloading from both sides. The precise lifting mechanism of all trailers also enables the load to be lifted without jolting. Of course, the lifting height can be flexibly adjusted.

The future is already built into Linde's route and logistics trains. In digitized manufacturing, the demands for precision and punctuality are increasing. Machines, goods, commodities and transport systems communicate with each other to achieve unprecedented efficiency. In the future, logistics trains will travel completely autonomously through the plant halls. Today, Linde route or logistics trains are already equipped with powerful sensors, actuators and controls.

Frequently asked questions about tugger trains / logistics trains

There is no general answer to this question: A logistics train certainly does not create forklift-free production and cannot replace it. But it does shift the forklift processes to a specific region in the company.

Linde offers the frames of its logistics trains in different drive variants. On the one hand, without drive as a low-cost, economical entry-level segment for customers for whom electric drives do not play a role and, of course, also with electric drive for the hydraulic motors in the frame.

Do you still have questions?

Manfred

Brunner

Do you still have questions?

Fabian

Kugelmann

You might also be interested in

- Thanks to modern steering systems and tight turning circles, Linde's tractors & platform trucks ensure high handling rates even in difficult places.

- You need a forklift or lift truck that is not off the shelf? Our special construction specialists will customize your vehicle according to your wishes.

- From A for collision protection to Z for fork positioner - at GRUMA you can get the right forklift and warehouse logistics accessories.

- Do you need service for forklifts or agricultural machinery? Whether maintenance, repair, testing or tire service - in our vast service network you are well taken care of.

You still have questions about our tugger trains?

Here you can make a non-binding request. Please leave us a message. We will get back to you immediately.