Narrow aisle equipment Linde A

1500 kg

12850 mm

Electric

Are you interested in this product?

Product description

The K combination vehicle from Linde Material Handling enables high handling performance for picking and handling processes in high-bay warehouses. This is made possible by powerful drives: the vehicle accelerates and lifts at the same time. In addition, the travel speed remains high even at high lifting heights and a large residual load capacity is available. Various assistance systems are available to help navigate through the warehouse with pinpoint accuracy or avoid obstacles. Last but not least, Linde System Control improves handling performance: depending on the version, the system adapts lifting, travel and auxiliary movements to the transport weight and lifting height. Several versions are available for the mast, chassis, battery and cab of the narrow-aisle truck, each of which can be combined according to the application requirements. This means that around 10 million vehicle configurations are possible.

Features

The lateral seating position provides optimum visibility, both when driving forward and in reverse. The operator keeps an even better eye on the load at great heights with the optional fork camera and cross-line laser. The systems facilitate load handling on upper racking levels and reduce the risk of accidents. The optional Dynamic Reach Control (DRC) intelligently adjusts the reach to the current load weight and reduces lateral mast sway during storage and retrieval. These features enhance safety and handling performance. A service technician can program travel, lift and lower stops. This prevents unintentional lifting or lowering of the load during travel. The aisle safety assistant, available as an optional extra, uses RFID tags or barcodes to determine its horizontal position in the aisle, then reacts to uneven floors or obstacles on the rack or ceiling and adjusts the lift height and speed accordingly. The personal protection system (PSA), which is also optional, uses sensors at the front and rear to detect whether there are people or objects in the travel path and stops the vehicle.

- Optimal view due to lateral seating position

- Dynamic Reach Control (DRC) reduces mast fluctuations during storage and retrieval

- Presettable travel, lift and lowering stops

- Optional personal protection equipment (PPE)

The operator effortlessly operates the lifting axis with an ergonomically shaped multifunction joystick. Driving comfort is ensured by the large cab, the seat with many adjustment options, and the intuitive arrangement of all controls. Because of the lateral seating position, the operator has a good view in every direction, avoiding strenuous body turns. A soft, non-slip floor mat and an optional air-suspended seat ensure that fewer jolts and vibrations are transmitted to the driver. A color display shows all information at a glance.

- Ergonomic, intuitive joystick

- Seat with many adjustment options

- Cabin with storage facilities

- Color display shows essential information

Even at great lifting heights, the high-rack truck reaches high speeds with its drive technology. In addition, many assistance and camera systems are available for handling at great heights - for example, the automated fork cycle. At the push of a button, the truck independently performs three movements when storing or retrieving a pallet. A great help for the operator is the combination of optional fork camera and also optional cross-line laser: the laser helps to pick up the pallet precisely, and the fork camera provides optimal visibility of the load when storing in high racking levels and ensures higher handling performance. The vehicle can be integrated into an optionally available warehouse navigation system. This allows the narrow aisle truck to automatically reach the desired pallet position along the fastest and most efficient route. The system works with RFID technology or barcodes. Depending on requirements, the truck can be equipped with swiveling push forks or telescopic forks.

- Optional fork camera and cross line laser facilitate load handling

- Modern assistance systems

- Numerous positioning aids

- Electronic support functions

Overall, the robust and durable technology of the A high-rack truck ensures low service and life cycle costs. The CAN bus connection guarantees simple service processes: All vehicle data can be read out and checked via a notebook. Batteries can be replaced quickly with the aid of a swap trolley.

- CAN bus connection

- Quick battery replacement

- Robust vehicle construction

Model overview

Model | Load capacity | Lifting height | Driving speed with/without load | Working aisle width for pallet 800 x 1200 lengthwise | Battery voltage / nominal capacity K5 |

|---|---|---|---|---|---|

A-Example 1 | 1,0 (t) | 7600 (mm) | 10.5 / 10.5 km/h | 1740 (mm) | 48 / 700 (V)/(Ah) o. kWh

|

A-Example 2 | 1,35 (t) | 7450 (mm) | 10.5 / 10.5 km/h | 1665 (mm) | 48 / 980 (V)/(Ah) o. kWh

|

A-Example 3 | 1,5 (t) | 12850 (mm) | 10.5 / 10.5 km/h | 1765 (mm) | 48 / 1120 (V)/(Ah) o. kWh

|

Special equipment

The combination of fork camera and cross-line laser makes load handling much easier. The cross-line laser helps to target the pallet in order to pick it up precisely. And the fork camera provides optimum visibility of the load when storing and retrieving at high rack levels.

This system combines all LSC functions and provides intelligent load stabilization. When storing and retrieving loads, it adjusts the reach according to the current load weight and eliminates lateral mast vibrations. This enables faster movement of loads and reduces damage to loads and racking.

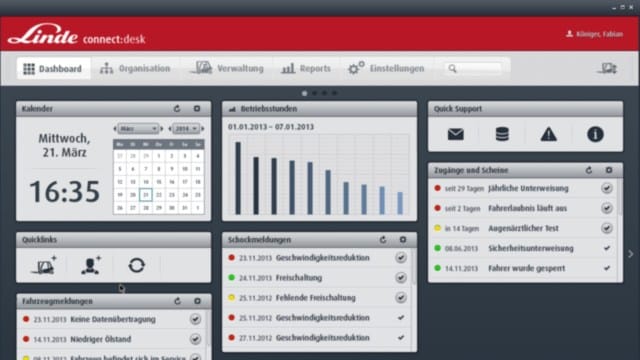

How and by whom are the individual vehicles used? What does the consumption data of the vehicles look like and is each one roadworthy? The interplay of software and hardware enables the connect fleet management system to provide the relevant answers.

The Linde BlueSpot™ driveway warning system increases safety during operation, as the LED spotlight makes trucks silently visible.

Features

The lateral seating position provides optimum visibility, both when driving forward and in reverse. The operator keeps an even better eye on the load at great heights with the optional fork camera and cross-line laser. The systems facilitate load handling on upper racking levels and reduce the risk of accidents. The optional Dynamic Reach Control (DRC) intelligently adjusts the reach to the current load weight and reduces lateral mast sway during storage and retrieval. These features enhance safety and handling performance. A service technician can program travel, lift and lower stops. This prevents unintentional lifting or lowering of the load during travel. The aisle safety assistant, available as an optional extra, uses RFID tags or barcodes to determine its horizontal position in the aisle, then reacts to uneven floors or obstacles on the rack or ceiling and adjusts the lift height and speed accordingly. The personal protection system (PSA), which is also optional, uses sensors at the front and rear to detect whether there are people or objects in the travel path and stops the vehicle.

- Optimal view due to lateral seating position

- Dynamic Reach Control (DRC) reduces mast fluctuations during storage and retrieval

- Presettable travel, lift and lowering stops

- Optional personal protection equipment (PPE)

The operator effortlessly operates the lifting axis with an ergonomically shaped multifunction joystick. Driving comfort is ensured by the large cab, the seat with many adjustment options, and the intuitive arrangement of all controls. Because of the lateral seating position, the operator has a good view in every direction, avoiding strenuous body turns. A soft, non-slip floor mat and an optional air-suspended seat ensure that fewer jolts and vibrations are transmitted to the driver. A color display shows all information at a glance.

- Ergonomic, intuitive joystick

- Seat with many adjustment options

- Cabin with storage facilities

- Color display shows essential information

Even at great lifting heights, the high-rack truck reaches high speeds with its drive technology. In addition, many assistance and camera systems are available for handling at great heights - for example, the automated fork cycle. At the push of a button, the truck independently performs three movements when storing or retrieving a pallet. A great help for the operator is the combination of optional fork camera and also optional cross-line laser: the laser helps to pick up the pallet precisely, and the fork camera provides optimal visibility of the load when storing in high racking levels and ensures higher handling performance. The vehicle can be integrated into an optionally available warehouse navigation system. This allows the narrow aisle truck to automatically reach the desired pallet position along the fastest and most efficient route. The system works with RFID technology or barcodes. Depending on requirements, the truck can be equipped with swiveling push forks or telescopic forks.

- Optional fork camera and cross line laser facilitate load handling

- Modern assistance systems

- Numerous positioning aids

- Electronic support functions

Overall, the robust and durable technology of the A high-rack truck ensures low service and life cycle costs. The CAN bus connection guarantees simple service processes: All vehicle data can be read out and checked via a notebook. Batteries can be replaced quickly with the aid of a swap trolley.

- CAN bus connection

- Quick battery replacement

- Robust vehicle construction

Technical data

- Designation: Narrow aisle equipment Linde A

| Drive type | Electric |

|---|---|

| Load capacity (kg) | 1500 |

| Lifting height (mm) | 12850 |

| Driving speed with/without load | 10.5 / 10.5 km/h |