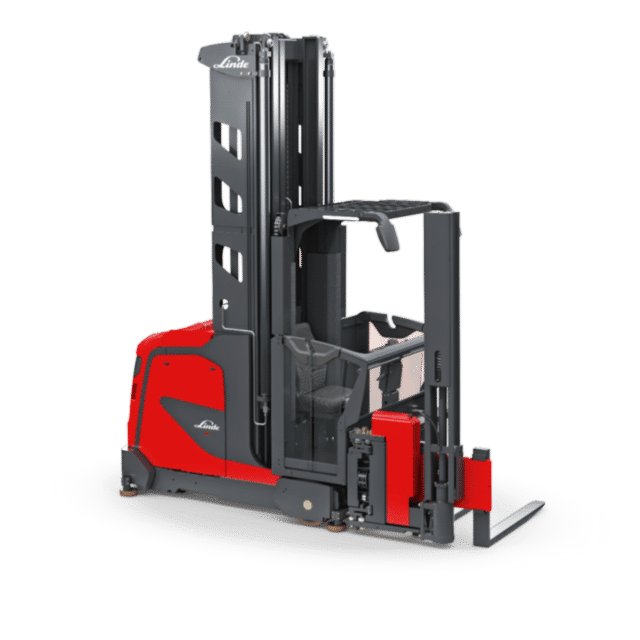

Narrow aisle equipment Linde K

1500 kg

18110 mm

Electric

Are you interested in this product?

Product description

Features

The driver must touch three points, otherwise he cannot move the combination vehicle: the hand sensors on the control panel and the dead man's switch on the cab floor. This prevents incorrect operation, which can lead to accidents. The driver's safety is also ensured by electrically monitored side barriers, which must be closed from a platform height of 1.2 meters. The optional personal protection system continuously scans the narrow aisle using a scanner and stops the vehicle if people are in the vicinity. Additional safety is provided by an optional aisle safety assistant, which detects unevenness marked with RFID tags or barcodes, obstacles in the racking, on the floor or on the ceiling and automatically limits the travel and lifting speed, lifting height or fork extension at these points. Service technicians can flexibly program general travel, lifting and lowering stops in the truck system. The "Linde System Control" assistance system - in the Standard, Load and Weight versions - supports the driver by adjusting the speed and optimizing driving behavior depending on the lift height, load detection and load weight.

- Three-point control

- Electrically monitored side barriers

- Aisle safety assistant

- Presettable travel, lift and lowering stops

- Optional personal protection system

- Linde System Control (Standard, Load, Weight)

- Dynamic Reach Control

- Rescue Alarm

The new control panel has an ergonomic shape. In addition, its position can be precisely adjusted with three axes - for example, for comfortable working while standing or sitting. The operator can also adjust the height and tilt of the folding seat. The control panel's color display clearly shows all important information at a glance, such as time, speed, lift height and steering angle.For the large and draught-protected cab, many storage options are available to make work easier. The chassis and cab are decoupled from each other so that less vibration reaches the operator. A tilt barrier is available as an option. It folds outward when the operator leans against it. This reduces his distance from the rack and thus makes picking easier.

- Control panel adjustable in height, inclination and angle

- Split control panel for full pallet handling, especially while seated

- Large cabin with best view of forks and load

- Seat height, inclination and angle individually adjustable

- Storage options available

- Optional tilt barrier

- Knee pads for comfortable picking

The modern drive technology of the combination vehicle generates a high travel speed even at high lift heights. Added to this are a high residual load capacity and modern RFID assistance systems, which make navigation in the warehouse and handling at the rack faster. When using the Linde Connect fleet management system, it is also possible to optimize the entire usage cycle of the vehicles. Additional handling support is provided by functions such as automatic lift height preselection or the automatic fork cycle. Here, the vehicle automatically executes three movements when retrieving a pallet at the push of a button. In the new version of the K, the main and auxiliary lift can be raised or lowered simultaneously. This enables the operator to move to high racking compartments in one step, for example, without having to operate the main and auxiliary strokes in succession. The forks can be positioned much faster and are particularly easy to control to the individual comfort height. The energy generated during braking and lowering is fed back into the battery. This improves operating time and economy in equal measure.

- High driving speed at high altitudes

- Modern assistance systems

- Many positioning aids

The robust technology of the K combination vehicle stands for low service costs and a long service life. Its CAN bus connection makes it possible to quickly diagnose and remedy technical problems via notebook. The two independent braking systems are maintenance-free, as are the three-phase motors for lifting and travel. With the optionally available battery transport rack, the lateral battery change runs quickly.

- CAN bus connection

- Low-wear braking systems

- Quick battery replacement

Videos & Pictures

Model overview

Model | Load capacity | Lifting height | Driving speed with/without load | Working aisle width for pallet 800 x 1200 lengthwise | Battery voltage / nominal capacity K5 |

|---|---|---|---|---|---|

K example 0.7 | 0,7 (t) | 5600 (mm) | 9 / 9 km/h | 1645 (mm) | 48 / 775 (V)/(Ah) o. kWh

|

K example 0.9 | 0,9 (t) | 7200 (mm) | 14 / 14 km/h | 1950 (mm) | 80 / 840 (V)/(Ah) o. kWh

|

K example 1.5 | 1,5 (t) | 15650 (mm) | 10.5 / 10.5 km/h | 1900 (mm) | 80 / 930 (V)/(Ah) o. kWh |

Special equipment

The forklift can be customized in many ways. For example, different engines, batteries, lift masts and chassis are available. Linde also configures the driver's cab individually with the help of different seat variants and storage options. This enables over 10 million configuration variants.

The vehicle cabin can be supplemented with many individual attachments, such as a monitor, terminal scanner, storage options and desk pad.

When the operator leans against the barrier, it tilts outward by ten centimeters. This gives him better access to the rack and makes picking easier.

This equipment package includes a large rearview mirror and side work lights that illuminate the work environment in the rack. Also available as an option is a ventilation system that cools the operator in the heat at higher lift heights.

This system combines all LSC functions and provides intelligent load stabilization. When storing and retrieving loads, it adjusts the reach according to the current load weight and eliminates lateral mast vibrations. This enables faster movement of loads and reduces damage to loads and racking.

How and by whom are the individual vehicles used? What does the consumption data of the vehicles look like and is each one roadworthy? The interplay of software and hardware enables the connect fleet management system to provide the relevant answers.

Features

The driver must touch three points, otherwise he cannot move the combination vehicle: the hand sensors on the control panel and the dead man's switch on the cab floor. This prevents incorrect operation, which can lead to accidents. The driver's safety is also ensured by electrically monitored side barriers, which must be closed from a platform height of 1.2 meters. The optional personal protection system continuously scans the narrow aisle using a scanner and stops the vehicle if people are in the vicinity. Additional safety is provided by an optional aisle safety assistant, which detects unevenness marked with RFID tags or barcodes, obstacles in the racking, on the floor or on the ceiling and automatically limits the travel and lifting speed, lifting height or fork extension at these points. Service technicians can flexibly program general travel, lifting and lowering stops in the truck system. The "Linde System Control" assistance system - in the Standard, Load and Weight versions - supports the driver by adjusting the speed and optimizing driving behavior depending on the lift height, load detection and load weight.

- Three-point control

- Electrically monitored side barriers

- Aisle safety assistant

- Presettable travel, lift and lowering stops

- Optional personal protection system

- Linde System Control (Standard, Load, Weight)

- Dynamic Reach Control

- Rescue Alarm

The new control panel has an ergonomic shape. In addition, its position can be precisely adjusted with three axes - for example, for comfortable working while standing or sitting. The operator can also adjust the height and tilt of the folding seat. The control panel's color display clearly shows all important information at a glance, such as time, speed, lift height and steering angle.For the large and draught-protected cab, many storage options are available to make work easier. The chassis and cab are decoupled from each other so that less vibration reaches the operator. A tilt barrier is available as an option. It folds outward when the operator leans against it. This reduces his distance from the rack and thus makes picking easier.

- Control panel adjustable in height, inclination and angle

- Split control panel for full pallet handling, especially while seated

- Large cabin with best view of forks and load

- Seat height, inclination and angle individually adjustable

- Storage options available

- Optional tilt barrier

- Knee pads for comfortable picking

The modern drive technology of the combination vehicle generates a high travel speed even at high lift heights. Added to this are a high residual load capacity and modern RFID assistance systems, which make navigation in the warehouse and handling at the rack faster. When using the Linde Connect fleet management system, it is also possible to optimize the entire usage cycle of the vehicles. Additional handling support is provided by functions such as automatic lift height preselection or the automatic fork cycle. Here, the vehicle automatically executes three movements when retrieving a pallet at the push of a button. In the new version of the K, the main and auxiliary lift can be raised or lowered simultaneously. This enables the operator to move to high racking compartments in one step, for example, without having to operate the main and auxiliary strokes in succession. The forks can be positioned much faster and are particularly easy to control to the individual comfort height. The energy generated during braking and lowering is fed back into the battery. This improves operating time and economy in equal measure.

- High driving speed at high altitudes

- Modern assistance systems

- Many positioning aids

The robust technology of the K combination vehicle stands for low service costs and a long service life. Its CAN bus connection makes it possible to quickly diagnose and remedy technical problems via notebook. The two independent braking systems are maintenance-free, as are the three-phase motors for lifting and travel. With the optionally available battery transport rack, the lateral battery change runs quickly.

- CAN bus connection

- Low-wear braking systems

- Quick battery replacement

Technical data

- Designation: Narrow aisle equipment Linde K

| Drive type | Electric |

|---|---|

| Load capacity (kg) | 1500 |

| Lifting height (mm) | 18110 |

| Driving speed with/without load | 14 / 14 km/h |