Linde Safety Pilot

The risk of falling over with a counterbalanced truck is very low - but not zero. If a forklift tips over, the driver's life can be endangered and major damage is caused to the vehicle and the load. Often, the cause lies with the driver.

To reduce "human error", Linde has developed a unique driver assistance system: The Linde Safety Pilot (LSP) sets new standards in terms of safety and assists the driver in two versions. Both the LSP-Select and the LSP-Active help the operator to keep an eye on the most important parameters at all times. Critical vehicle conditions are detected at an early stage and communicated to the driver. The Active version of the Linde Safety Pilot also automatically intervenes in the driving and lifting functions of the forklift truck.

For your safety

Reduces the risk of tipping accidents

Avoids driving errors

Warns of dangers in time

Do not rely on your own feeling

Tipping accidents with a counterbalanced truck are dangerous and often difficult for the driver to avoid. Especially when frequently changing and unknown loads are transported.

The driver must know and precisely evaluate relevant dimensions such as load weight, load center distance and the desired displacement in order to ensure his own driving safety. This is not realistic.

In practice, gut feeling is often the deciding factor. In both the Active and Select versions, the LSP has various sensors that measure data such as lift height, fork tilt and load weight at different points on the vehicle.

These central values are displayed on a monitor in the driver's cab. The driver no longer has to estimate the weight of the goods to be transported or the current lifting height, but always has the hazard situation in view on this basis.

The new benchmark in safety

Three versions are displayed by the LSP monitor

- Safe working area: There are no restrictions.

- Limit range: The display lights up orange - the load limit has now almost been reached. LSP-Active reduces stroke tilting speed.

- Critical area: The display lights up red - the payload display has finally been reached. A warning tone also sounds. LSP-Active regulates the vehicle functions.

The comfort functions of the LSP Select and Active

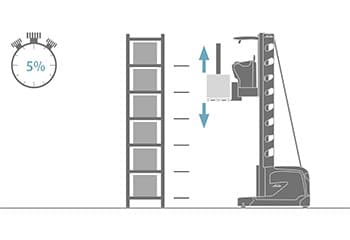

Stroke height preselection

The forklift operator can set the height to which the goods are to be lifted before the journey begins. During handling, he no longer has to readjust and thus saves a lot of time.

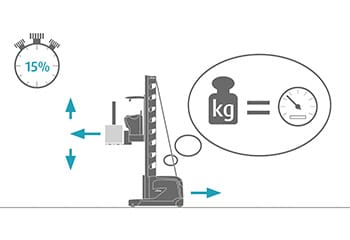

Integrated load scale

The integrated load scale weighs the goods in seconds and also includes an adding function. The driver can thus quickly see, for example, whether the maximum load of a truck has been reached.

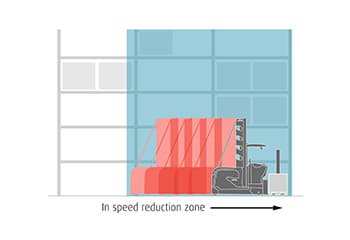

Speed reduction

If the driver accelerates the truck too much, brakes too hard or drives through curves at high speed, LSP-Active influences the driving function. The system compensates for driving errors and prevents tip-over accidents.

LSP Select | LSP-Active | |

|---|---|---|

Display in monitor | - Load, lift height, tilt angle, travel speed, steering angle, preselected travel direction (2-pedal/1-pedal), travel drive temperatures | - Load, lift height, tilt angle, travel speed, steering angle, preselected travel direction (2-pedal/1-pedal), travel drive temperatures

- Additional display of current maximum permissible lift height, load center distance, current maximum permissible tilt angle. |

Active intervention | - Not possible | - Depending on lift height, tilt angle and travel speed (depending on the travel or load situation, etc.) |

Comfort functions | - Lift height preselection, tilt angle preselection, lift limitation, lowering limitation (fork wear protection), load scale (with tare function), load addition, driving dynamics setting, energy consumption display, speed limit. | - Lift height preselection, tilt angle preselection, lift limitation, lowering limitation (fork wear protection), load scale (with tare function), load addition, driving dynamics setting, energy consumption display, speed limit. |

Innovations for more safety

A highly sensitive sensor measures the pressure in the hydraulic system of the mast. Together with known values such as cylinder diameter and hoist chain ratio, this allows the current load weight to be determined.

The associated sensors are integrated as standard in all Linde counterbalance trucks.

A newly developed measuring cell is located on the rear axle, which can be used to calculate the load torque or the distance of the load center of gravity from the front axle.

Do you still have questions?

Mathias

Kastner

How does a tipping accident happen in the first place?

- The driver picks up the load with the forklift.

- The stacker travels with the load lifted.

- If the driver brakes with the load lifted, the truck begins to tip.

- The vehicle overturns.

You might also be interested in

- The Linde Safety Guard is an asset in terms of occupational safety: warning tones, flashing LEDs or vibration alarms actively protect employees from danger.

- Reversing sensors for forklifts? The "Linde Motion Detection" assistance system makes it possible. The retrofittable sensors warn warehouse personnel of collisions in real time.

- Do you care about protecting your drivers? Then be sure to take a look at our restraint systems for forklift trucks.

- Safety in operation always has top priority. With clever assistance systems and safety devices, you specifically prevent accidents.

Are you interested in the Linde Safety Pilot?

Here you can make a non-binding request. Please leave us a message. We will get back to you immediately.