Ramming and collision protection for racks

Did you know that 90 percent of all rack damage is caused by forklifts? The reason: The driver must always keep an eye on the goods and at the same time keep an eye on the distance between the rack and the forklift while storing and retrieving goods in the upper rack levels. Even a brief moment of lack of concentration can lead to a collision . Damaged racks, vehicles and falling stored goods can be the result.

The Linde Rack Protection Sensor not only saves repair costs here, but also increases safety during operation. The assistance systemcontinuously monitors the distance between the truck and the rack and automatically brakes the truck before a collision occurs.

Avoid shelf damage

With the Linde Rack Protection Sensor

Why is collision protection necessary at all?

Protection of man and machine

Particularly when storing and retrieving goods at great heights, full concentration is required on the part of the driver. On the one hand, he must ensure that the load is placed safely in the rack. At the same time, he must also keep an eye on the distance between the forklift and the rack in order to avoid a collision and the associated damage to man and machine. After all, damage to or even collapse of the racking can result in long downtimes and high repair costs. In addition, people can be injured by the falling warehouse goods.

This can be avoided by a suitable rack collision protection. Especially in companies with a high proportion of new or temporary employees, this measure proves to be particularly advantageous, as these people often lack experience and misjudge the dimensions of the forklift.

Digital collision protection vs. classic impact protection

Collision damage to racks, goods and vehicles can result in high repair costs and expenses for protective devices.

Classic protective devices basically offer good protection here. However, they have to be replaced after some time due to new damage. In addition, the classic guards do not provide reliable protection against the goods located on the lower shelf levels.

Our digital collision protection, on the other hand, is a one-time investment with no follow-up costs. However, as this is currently only available for reach trucks, the classic variant must still be used for other types of trucks.

Increased productivity and maximum shelf capacity

By using the Rack Protection Sensor, accidents to rack columns and goods stored on the floor are prevented, safety in the warehouse is increased and repair costs are saved. With fewer racks failing due to damage, full rack capacity can now be utilized, significantly increasing productivity.

In addition, the driver can now devote his full attention to storing and retrieving the goods, which contributes to higher handling performance.

How the Linde Rack Protection Sensor works

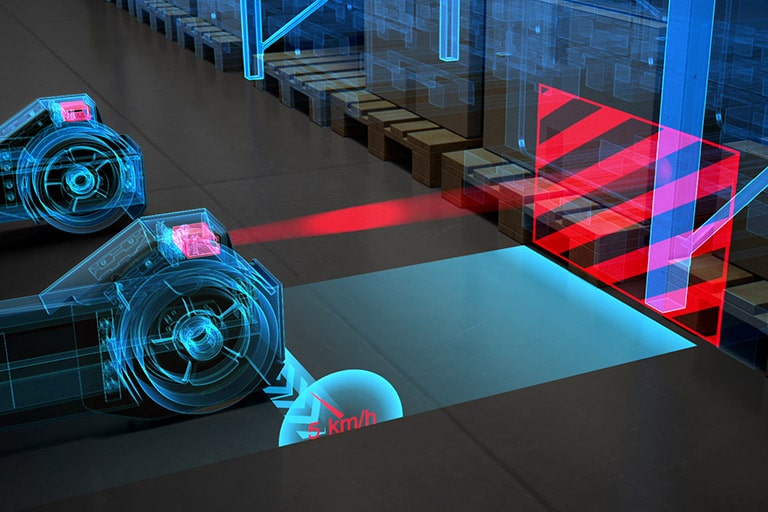

The Linde Rack Protection Sensor is an alternative to classic impact protection. The assistance system acts as digital collision protection by continuously monitoring the distance between the reach truck and the rack or goods.

Similar to the parking sensors in a car, the distance to the obstacle is measured continuously. As soon as the reach truck enters the danger zone, the travel speed is automatically reduced and a warning tone sounds to warn the driver of the impending collision.

The sensors only switch on when the vehicle's speed falls below 5 km/h. The system remains inactive if the vehicle accelerates to a speed above this limit. If, on the other hand, the vehicle accelerates to a speed above this set limit, the system remains inactive.

Clever brake assistant

The Rack Protection Sensor automatically scans its surroundings from a travel speed of less than 5 km/h and detects any potential obstacle within a radius of 5 meters.

If an obstacle is detected by the system, the distance between the obstacle and the vehicle is measured. If the speed of the truck is too high at the measured distance, the Rack Protection Sensor automatically reduces the speed of the vehicle .

Proportional braking

As soon as the truck approaches a potential obstacle, the Rack Protection Sensor brakes the vehicle proportionally depending on the distance to the obstacle and the current travel speed. This prevents the vehicle from coming to a sudden stop, which could endanger the driver or the load. Pallets can still be pushed with wheel arms. If the sensor detects a constant distance to the pallet, the Rack Protection Sensor remains inactive.

Perfect vision thanks to polarized light

The Linde Rack Protection Sensor uses polarized light sensors for distance measurement. Even in difficult visibility conditions, these sensors impress with their high precision. Regardless of the color of the artificial or natural light, the sensor's red LED dot is clearly visible and provides the driver with additional orientation during demanding warehouse maneuvers.

For which trucks is the assistance system available?

The Linde Rack Protection Sensor is available as an option for all Performance vehicles in the 1120 reach truck series (R14, R14HD, R16, etc.) in the payload range from 1.4 to 2.5 tons. For older trucks, there will also soon be a retrofit option for the assistance system.

The assistance system can also currently be ordered on all Wide vehicles (R14W HD both chassis widths, R20W both chassis widths & R25W). In connection with the models of the B version, G version and N version, the system is currently not available.

Your advantages

Innovative collision and impact protection for racks

Unique system on the market - Only available for Linde trucks

Protection of man and machine

Reduction of repair and service costs

Avoidance of collisions through automatic braking

No downtime from damaged racks & vehicles

Advantageous when using temporary or contract workers

Increased productivity & maximum shelf capacity

Further assistance systems for more safety

Linde BlueSpot

For more safety: To warn pedestrians and other forklift drivers, the Linde BlueSpot projects a blue warning dot onto the floor.

Linde Safety Pilot

For more safety in operation: The Linde Safety Pilot warns your drivers of hazards, reduces the risk of tipping accidents and avoids driving errors.

Linde Safety Guard

The Linde Safety Guard is an asset in terms of occupational safety: warning tones, flashing LEDs or vibration alarms actively protect employees from danger.

Linde Motion Detection

Reversing sensors for forklifts? Linde Motion Detection makes it possible. The retrofittable sensors warn warehouse personnel of collisions in real time.

New innovative equipment options for reach trucks

A sensor that prevents collision damage to the rack and a multifunction lever that provides efficient control of travel, push and lift functions that is easy on the joints.

Read all about the two new innovative equipment options for reach trucks from Linde Material Handling in our blog post now.

You might also be interested in

- Safety in operation always has top priority. With clever assistance systems and safety devices, you specifically prevent accidents.

- From pallet racking to large-shelf racking, shelving or mobile racking systems, flow racking to shuttle systems - we supply everything from a single source!

- All GRUMA services for your racks compactly at a glance: from maintenance and repairs to planning new racks.

- Rack testing or rack inspection is required by law in a company. We inspect your warehouse during operation.

Are you interested in the Rack Protection Sensor?

Here you can make a non-binding request. Please leave us a message. We will get back to you immediately.