All important energy data at a glance: The new connect:charger module of the fleet management solution from Linde Material Handling (MH) brings transparency to the charging processes of battery-powered industrial trucks. Prioritization, defined charging time windows and power limits can thus sustainably reduce electricity costs - while maintaining a consistently high level of vehicle availability. The industry-independent software and hardware solution can be installed quickly and used profitably even with a small fleet.

Especially operators of industrial trucks with lithium-ion batteries are often familiar with these power load peaks. Here, the batteries are usually charged again and again during the day in order to constantly extend their runtime. However, if a large number of employees charge their e-trucks and warehouse equipment at the same time - for example, during breaks or after the end of a shift - then the power demand increases rapidly. In addition, fast charging of lithium-ion batteries is associated with a significantly higher power demand than is the case with a lead-acid battery.

But even for companies for which limit values are not relevant, it is worth considering the use of a charging management system. Particularly with growing fleets, it is sometimes difficult to make a decision about the appropriate time to charge the devices in order to ensure the availability of the vehicles or to shift charging to times of day with favorable electricity rates.

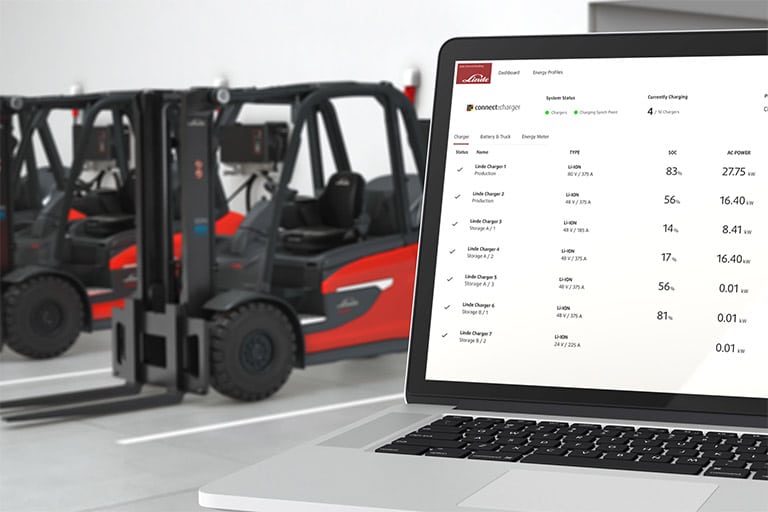

In the new Linde system, up to 50 loaders are networked with a central hardware unit, which automatically controls the power query according to predefined rules. The forklift drivers and fleet operators can then view all relevant information via a dashboard. There they can see, for example, when a particular industrial truck will be ready for use again or how much energy the individual chargers have consumed over the day. The charging behavior can also be adapted to operational requirements there with just a few clicks.

The intelligent charging management algorithm coordinates the various specifications and allocates appropriate capacities to the chargers.

For the transmission of data from the chargers to the control unit, a wired solution (for up to 50 chargers) will initially be available at market launch. A wireless variant is also already planned. In addition, further software functions are to be integrated in the future: from dynamic load management and a cloud-based application to the integration of the charging management solution into a holistic energy management solution. Retrofitting of the Linde connect: charger is possible, provided that the chargers have an integrated interface (from date of manufacture 2018).