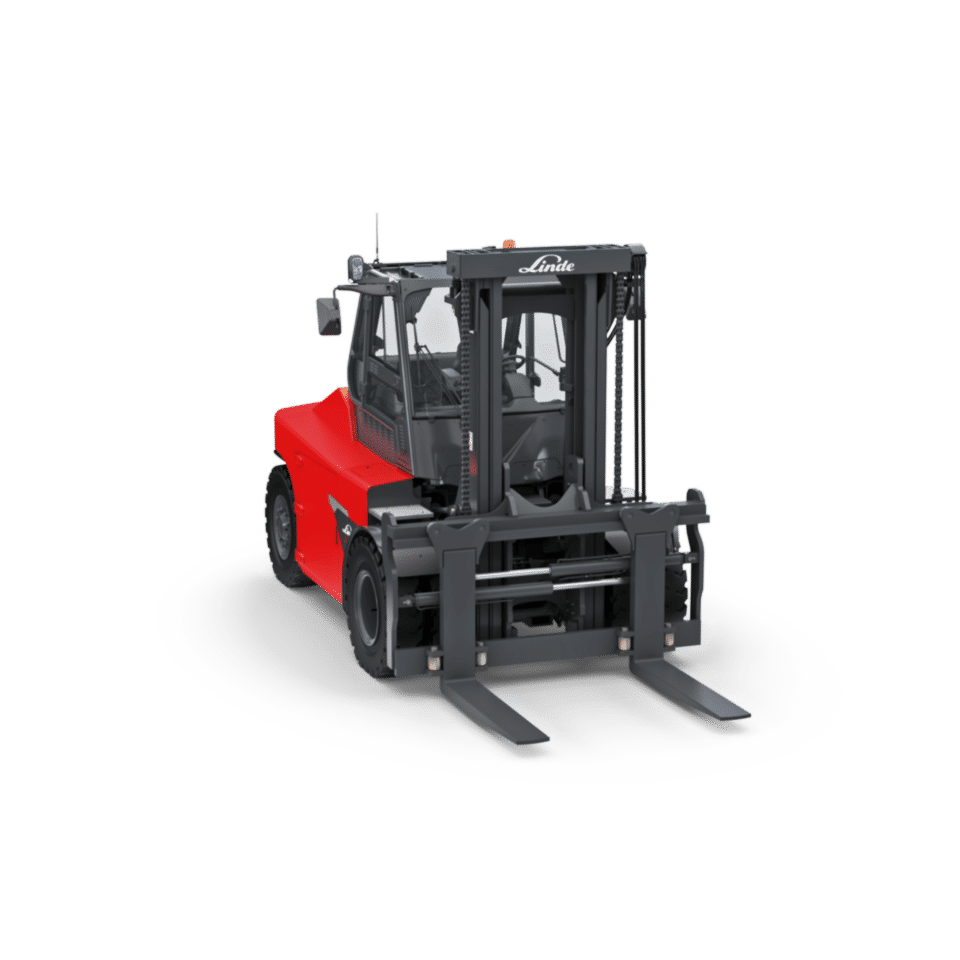

Electric forklift Linde E100 - E180

18000 kg

7000 mm

Electric

Are you interested in this product?

Product description

The E100 - E180 electric heavy-duty forklifts from Linde are the most powerful in their class. They combine the best of both worlds of electric and v-type forklifts: The series combines the power development characteristic of diesel vehicles with the environmentally friendly, quiet and dynamic operation of electric forklifts. The new heavy-duty trucks can transport and stack loads weighing up to 18,000 kilograms at heights of up to ten meters. The electric forklifts draw their energy from either two lead-acid or two lithium-ion batteries. Customers can therefore choose between a cost-efficient variant for light to medium applications and equipment for demanding tasks and high workloads. Even a battery change for 24/7 applications is quickly possible. Thanks to the powerful electric motors, the new heavy-duty trucks are in no way inferior to Linde's highest-performing V trucks to date, putting them at the top of the performance league.

Features

The E100 - E180 heavy-duty forklifts are designed to provide the best visibility in all directions. The view to the rear is unobstructed. To both sides, glass doors allow an unrestricted view, which prevents collisions and accidents. Thanks to the visibility-optimized lift masts and the safety glass roof, the driver can also keep a perfect view of the goods being transported during storage and retrieval. This contributes to safe and precise load handling. The batteries integrated into the chassis not only contribute to excellent visibility, but also shift the vehicle's center of gravity downward. As a result, the heavy-duty trucks are characterized by high stability.

- Excellent all-round visibility

- Visibility optimized masts

- Armored glass roof facilitates load handling

- High stability due to low center of gravity

Thanks to the compact chassis that integrates both batteries, the heavy-duty trucks offer excellent visibility in all directions. In addition, the physical strain on the driver is reduced by an excellent seating position: He can transport, store and retrieve loads for many hours in a relaxed and fatigue-free manner. The precise driving characteristics, which allow the trucks to be moved with millimeter accuracy, also contribute to the comfortable driving experience. At the same time, they are almost silent on the road and reduce the hearing strain on employees. The electric forklifts also contribute to a healthy working environment thanks to their emission-free drive technology.

- Relaxed seating position due to all-round visibility

- Precise driving behavior

- Low noise emission

Regardless of whether the electric heavy-duty trucks are only in use for a few hours or non-stop: Each customer can select the energy system that suits them best and choose either a lower-priced lead-acid battery pair for light to medium applications or the lithium-ion system for demanding transports under continuous full load. Should the application change in later customer use, the battery technologies can be exchanged easily and without further adaptation on the vehicle. This guarantees the best flexibility. The electric motors ensure exceptionally dynamic acceleration, which contributes to outstanding handling performance. The excellent all-round visibility enables precise handling of large and heavy loads.

- Flexible adaptation to any customer application

- Choice between lead-acid and lithium-ion battery

- Cost-efficient variant for light applications

- Dynamic driving behavior

Thanks to the tilting cab, all technical components are easily accessible, which simplifies repairs and reduces maintenance-related downtimes. The standard components used make repairs even easier. The batteries can be replaced within a few minutes. It is possible to switch between lead-acid and lithium-ion batteries at any time without having to replace any other hardware.

- Easily accessible service components

- Standard components simplify repairs

- Fast, easy battery replacement

Model overview

Model | Load capacity | Load center distance | Wheelbase | Turning radius | Driving speed with/without load |

|---|---|---|---|---|---|

E100/1200 | 10,0 (t) | 1200 (mm) | 3000 (mm) | 4102 (mm) | 18 / 20 [23/25] km/h |

E100/600 | 10,0 (t) | 600 (mm) | 3000 (mm) | 4102 (mm) | 18 / 20 [23/25] km/h

|

E120/1200 | 12,0 (t) | 1200 (mm) | 3250 (mm) | 4338 (mm) | 18 / 20 [23/25] km/h

|

E120/600 | 12,0 (t) | 600 (mm) | 3000 (mm) | 4102 (mm) | 18 / 20 [23/25] km/h

|

E140/1200 | 14,0 (t) | 1200 (mm) | 3250 (mm) | 4512 (mm) | 18 / 20 [23/25] km/h

|

E150/600 | 15,0 (t) | 600 (mm) | 3250 (mm) | 4338 (mm) | 18 / 20 [23/25] km/h

|

E160/1200 | 16,0 (t) | 1200 (mm) | 3500 (mm) | 4754 (mm) | 18 / 20 [23/25] km/h

|

E160/600 | 16,0 (t) | 600 (mm) | 3250 (mm) | 4338 (mm) | 18 / 20 [23/25] km/h

|

E180/600 | 18,0 (t) | 600 (mm) | 3250 (mm) | 4512 (mm) | 18 / 20 [23/25] km/h

|

E180/900 | 18,0 (t) | 900 (mm) | 3500 (mm) | 4754 (mm) | 18 / 20 [23/25] km/h

|

Special equipment

Available are hydraulic fork positioners of various types, multiple pallet clamp, rotating device, paper clamp, carrying mandrel and much more.

The image from the rear-view camera can be displayed on the integrated 7-inch display and ensures optimum visibility to the rear.

Features

The E100 - E180 heavy-duty forklifts are designed to provide the best visibility in all directions. The view to the rear is unobstructed. To both sides, glass doors allow an unrestricted view, which prevents collisions and accidents. Thanks to the visibility-optimized lift masts and the safety glass roof, the driver can also keep a perfect view of the goods being transported during storage and retrieval. This contributes to safe and precise load handling. The batteries integrated into the chassis not only contribute to excellent visibility, but also shift the vehicle's center of gravity downward. As a result, the heavy-duty trucks are characterized by high stability.

- Excellent all-round visibility

- Visibility optimized masts

- Armored glass roof facilitates load handling

- High stability due to low center of gravity

Thanks to the compact chassis that integrates both batteries, the heavy-duty trucks offer excellent visibility in all directions. In addition, the physical strain on the driver is reduced by an excellent seating position: He can transport, store and retrieve loads for many hours in a relaxed and fatigue-free manner. The precise driving characteristics, which allow the trucks to be moved with millimeter accuracy, also contribute to the comfortable driving experience. At the same time, they are almost silent on the road and reduce the hearing strain on employees. The electric forklifts also contribute to a healthy working environment thanks to their emission-free drive technology.

- Relaxed seating position due to all-round visibility

- Precise driving behavior

- Low noise emission

Regardless of whether the electric heavy-duty trucks are only in use for a few hours or non-stop: Each customer can select the energy system that suits them best and choose either a lower-priced lead-acid battery pair for light to medium applications or the lithium-ion system for demanding transports under continuous full load. Should the application change in later customer use, the battery technologies can be exchanged easily and without further adaptation on the vehicle. This guarantees the best flexibility. The electric motors ensure exceptionally dynamic acceleration, which contributes to outstanding handling performance. The excellent all-round visibility enables precise handling of large and heavy loads.

- Flexible adaptation to any customer application

- Choice between lead-acid and lithium-ion battery

- Cost-efficient variant for light applications

- Dynamic driving behavior

Thanks to the tilting cab, all technical components are easily accessible, which simplifies repairs and reduces maintenance-related downtimes. The standard components used make repairs even easier. The batteries can be replaced within a few minutes. It is possible to switch between lead-acid and lithium-ion batteries at any time without having to replace any other hardware.

- Easily accessible service components

- Standard components simplify repairs

- Fast, easy battery replacement

Technical data

- Description: Electric forklift Linde E100 - E180

| Drive type | Electric |

|---|---|

| Load capacity (kg) | 18000 |

| Lifting height (mm) | 7000 |

| Driving speed with/without load | 18 / 20 km/h |