Electric forklift Linde E20 - E35

3500 kg

7780 mm

Electric

Are you interested in this product?

Product description

Features

One of the most important safety features is the good visibility of the driver due to the slim mast design, the narrow A-pillar and the lowered front plate. The roof design also allows a largely unrestricted view upwards when storing and retrieving. The low vehicle center of gravity with high steering axle ensures tilt resistance in curves. The standard Linde Curve Assist additionally reduces the speed according to the steering angle. The Linde Load Assist, which is also integrated as standard, protects against accidents caused by falling loads. If the load is tilted too far forward during lifting, the assist system reduces the forward tilt and lifting speed depending on the lifting height.

- Optimal view of load and surroundings

- Tilt resistance in curves thanks to Linde Curve Assist

- Linde Load Assist prevents overturning due to overly heavy loads

The operator's cab is spacious and, with the ergonomic seat, offers a comfortable workplace that prevents tension and fatigue. The large field of vision allows a clear view in all directions, both of the load and the surrounding area. All essential controls are positioned immediately around the operator, reducing physical strain. The decoupling of the chassis from the steering axle and mast, with an additional elastomer ring bearing for shock absorption on the front axle, improves the driving experience even on uneven ground. Significantly less vibration and shock is transmitted to the operator. In addition, the noise level is reduced, for example due to rattling fork carriers or lift chains. Both reduce the physical strain on the operator and improve work performance.

- Spacious cabin with perfect view of load and surroundings

- Ergonomic seats with easy-to-reach controls

- Decoupling the workstation, drive, and mast increases

- Ride comfort

The E20 - E35 electric forklifts are exceptionally maneuverable thanks to the combination of two-motor front drive and patented combi steering axle. The overhead tilt cylinders in combination with the torsion-resistant mast design also ensure a high residual load capacity and safe load handling at lift heights of up to 6.50 meters. The new synchronous reluctance motor improves the performance characteristics of the trucks and measurably increases energy efficiency. The standardized design allows customers to freely choose the energy storage system between lead-acid, lithium-ion battery or fuel cell. This means that existing batteries can continue to be used, for example. Wireless access to vehicle data and control enables integration into logistics, safety and fleet management systems and analysis of information on vehicle use and condition.

- High maneuverability due to dual-motor front-wheel drive plus combined steering axle

- Mast design ensures safe handling up to a height of 6.50 meters

- Freely selectable energy storage

- Wireless connectivity enables data analysis and integration into digital processes

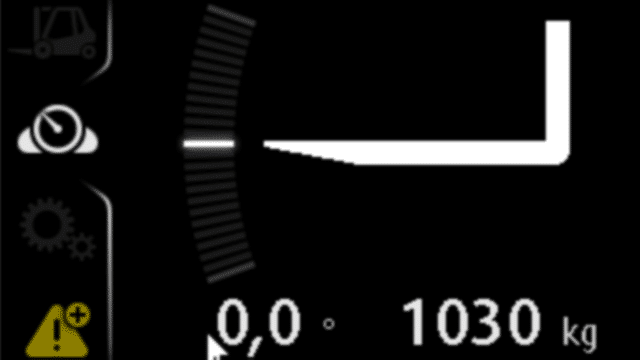

On the standard 3.5-inch display, the driver can see all important information at a glance, such as remaining driving time, warning lights and operating hours. The ability to remotely upload firmware updates and diagnose faults eliminates the need for a service technician to travel to the site. Service intervals are calculated on the basis of the permanently transmitted operating hours. Wear and any damage that may occur are identified at an early stage via remote diagnosis. Serious consequential damage can be avoided by timely maintenance or repair. Modular assemblies such as the mast or operator workstation can be replaced quickly and easily, which reduces downtimes for repairs.

- Simple maintenance

- Remote diagnostics and maintenance reduce service calls

- Replacement of modular assemblies shortens repair breaks

Model overview

Special equipment

Model | Load capacity | Lifting height | Driving speed with/one load | Battery voltage / nominal capacity K5 | K5 Aisle width for pallet 800 x 1200 |

|---|---|---|---|---|---|

E20 | 2,0 (t) | 3030 (mm) | 20 / 20 km/h | 80 / 460/500 (V)/(Ah) o. kWh | 3769 (mm)

|

E20 Container | 2,0 (t) | 3030 (mm) | 20 / 20 km/h | 80 / 460/500 (V)/(Ah) o. kWh | 3769 (mm) |

E20/600H | 2,0 (t) | 3330 (mm) | 20 / 20 km/h | 80 / 560/620 (V)/(Ah) o. kWh | 3803 (mm)

|

E20/600H Container | 2,0 (t) | 3330 (mm) | 20 / 20 km/h | 80 / 560/620 (V)/(Ah) o. kWh | 3803 (mm)

|

E25 | 2,5 (t) | 3030 (mm) | 20 / 20 km/h | 80 / 460/500 (V)/(Ah) o. kWh | 3769 (mm)

|

E25 Container | 2,5 (t) | 3030 (mm) | 20 / 20 km/h | 80 / 460/500 (V)/(Ah) o. kWh | 3769 (mm)

|

E25/600H | 2,5 (t) | 3295 (mm) | 20 / 20 km/h | 80 / 560/620 (V)/(Ah) o. kWh | 3837 (mm)

|

E25/600H Container | 2,5 (t) | 3295 (mm) | 20 / 20 km/h | 80 / 560/620 (V)/(Ah) o. kWh | 3837 (mm)

|

E25/600HL | 2,5 (t) | 3295 (mm) | 20 / 20 km/h | 80 / 700/775 (V)/(Ah) o. kWh | 3982 (mm)

|

E25/600HL Container | 2,5 (t) | 3295 (mm) | 20 / 20 km/h | 80 / 700/775 (V)/(Ah) o. kWh | 3982 (mm)

|

E25L | 2,5 (t) | 3030 (mm) | 20 / 20 km/h | 80 / 575/625 (V)/(Ah) o. kWh | 3910 (mm)

|

E25L Container | 2,5 (t) | 3030 (mm) | 20 / 20 km/h | 80 / 575/625 (V)/(Ah) o. kWh | 3910 (mm)

|

E30 | 3,0 (t) | 2995 (mm) | 20 / 20 km/h | 80 / 460/500 (V)/(Ah) o. kWh | 3888 (mm)

|

E30 Container | 3,0 (t) | 2995 (mm) | 20 / 20 km/h | 80 / 460/500 (V)/(Ah) o. kWh | 3888 (mm)

|

E30/600H | 3,0 (t) | 3295 (mm) | 20 / 20 km/h | 80 / 560/620 (V)/(Ah) o. kWh | 3835 (mm)

|

E30/600H Container | 3,0 (t) | 3295 (mm) | 20 / 20 km/h | 80 / 560/620 (V)/(Ah) o. kWh | 3835 (mm)

|

E30/600HL | 3,0 (t) | 3295 (mm) | 20 / 20 km/h | 80 / 700/775 (V)/(Ah) o. kWh | 3980 (mm)

|

E30/600HL Container | 3,0 (t) | 3295 (mm) | 20 / 20 km/h | 80 / 700/775 (V)/(Ah) o. kWh | 3980 (mm)

|

E30/600HL Beverages | 3,0 (t) | 4095 (mm) | 20 / 20 km/h | 80 / 700/775 (V)/(Ah) o. kWh | 3980 (mm)

|

E30L | 3,0 (t) | 2995 (mm) | 20 / 20 km/h | 80 / 575/625 (V)/(Ah) o. kWh | 3983 (mm)

|

E30L Container | 3,0 (t) | 2995 (mm) | 20 / 20 km/h | 80 / 575/625 (V)/(Ah) o. kWh | 3983 (mm)

|

E35HL | 3,5 (t) | 3295 (mm) | 20 / 20 km/h | 80 / 700/775 (V)/(Ah) o. kWh | 3980 (mm)

|

E35HL Container | 3,5 (t) | 3295 (mm) | 20 / 20 km/h | 80 / 700/775 (V)/(Ah) o. kWh | 3980 (mm)

|

E35L | 3,5 (t) | 2995 (mm) | 20 / 20 km/h | 80 / 575/625 (V)/(Ah) o. kWh | 4038 (mm)

|

E35L Container | 3,5 (t) | 2995 (mm) | 20 / 20 km/h | 80 / 575/625 (V)/(Ah) o. kWh | 4038 (mm)

|

The innovative Linde Steer Control concept from Linde Material Handling replaces the classic steering wheel with a mini steering wheel or joystick and increases ergonomics, precision and safety.

Tipping accidents with the counterbalanced truck can be largely avoided when using the Safety Pilot from Linde Material Handling.

Illuminated warning systems such as Linde BlueSpot™ and Linde TruckSpot project colored light dots or warning signs onto the floor to warn pedestrians and other vehicles.

The innovative Safety Guard assistance system from Linde warns vehicle operators and pedestrians of acute danger in the immediate vicinity of the vehicle by means of sounds and light signals.

The comfort cab protects the operator and offers excellent all-round visibility of the load and working environment with an armored glass roof and large glass doors.

The battery can be changed very easily, for example with a lift truck, by opening the side door from the right side.

A wide range of seats provides additional comfort and active protection against posture problems with features such as air suspension, lumbar support, seat heating or seat ventilation.

This optional function shows the driver the current load weight in the display.

The powerful air conditioning system with integrated heating and pollen filter ensures a pleasant working climate in the cab in summer and winter and prevents fogged windows.

* Contains fluorinated hydrocarbons

With its semicircular design, the Linde VertiLight illuminates the work area over a large area. The two-color light strips of the Linde LED Stripes illuminate the respective driving direction of the truck with white light.

The Linde Speed Assist driving assistance system automatically adjusts the vehicle's top speed to the surroundings and the driving situation.

In addition to the vehicle information, the 7-inch display can show, for example, the display for the Linde Safety Pilot or the image from mast or rear view cameras. The screen layout and displays can be customized.

Linde's connect fleet management system is used to manage the vehicle fleet. From maintenance planning and documentation of maintenance and repair history to access control.

Features

One of the most important safety features is the good visibility of the driver due to the slim mast design, the narrow A-pillar and the lowered front plate. The roof design also allows a largely unrestricted view upwards when storing and retrieving. The low vehicle center of gravity with high steering axle ensures tilt resistance in curves. The standard Linde Curve Assist additionally reduces the speed according to the steering angle. The Linde Load Assist, which is also integrated as standard, protects against accidents caused by falling loads. If the load is tilted too far forward during lifting, the assist system reduces the forward tilt and lifting speed depending on the lifting height.

- Optimal view of load and surroundings

- Tilt resistance in curves thanks to Linde Curve Assist

- Linde Load Assist prevents overturning due to overly heavy loads

The operator's cab is spacious and, with the ergonomic seat, offers a comfortable workplace that prevents tension and fatigue. The large field of vision allows a clear view in all directions, both of the load and the surrounding area. All essential controls are positioned immediately around the operator, reducing physical strain. The decoupling of the chassis from the steering axle and mast, with an additional elastomer ring bearing for shock absorption on the front axle, improves the driving experience even on uneven ground. Significantly less vibration and shock is transmitted to the operator. In addition, the noise level is reduced, for example due to rattling fork carriers or lift chains. Both reduce the physical strain on the operator and improve work performance.

- Spacious cabin with perfect view of load and surroundings

- Ergonomic seats with easy-to-reach controls

- Decoupling the workstation, drive, and mast increases

- Ride comfort

The E20 - E35 electric forklifts are exceptionally maneuverable thanks to the combination of two-motor front drive and patented combi steering axle. The overhead tilt cylinders in combination with the torsion-resistant mast design also ensure a high residual load capacity and safe load handling at lift heights of up to 6.50 meters. The new synchronous reluctance motor improves the performance characteristics of the trucks and measurably increases energy efficiency. The standardized design allows customers to freely choose the energy storage system between lead-acid, lithium-ion battery or fuel cell. This means that existing batteries can continue to be used, for example. Wireless access to vehicle data and control enables integration into logistics, safety and fleet management systems and analysis of information on vehicle use and condition.

- High maneuverability due to dual-motor front-wheel drive plus combined steering axle

- Mast design ensures safe handling up to a height of 6.50 meters

- Freely selectable energy storage

- Wireless connectivity enables data analysis and integration into digital processes

On the standard 3.5-inch display, the driver can see all important information at a glance, such as remaining driving time, warning lights and operating hours. The ability to remotely upload firmware updates and diagnose faults eliminates the need for a service technician to travel to the site. Service intervals are calculated on the basis of the permanently transmitted operating hours. Wear and any damage that may occur are identified at an early stage via remote diagnosis. Serious consequential damage can be avoided by timely maintenance or repair. Modular assemblies such as the mast or operator workstation can be replaced quickly and easily, which reduces downtimes for repairs.

- Simple maintenance

- Remote diagnostics and maintenance reduce service calls

- Replacement of modular assemblies shortens repair breaks

Technical data

- Description: Electric forklift Linde E20 - E35

| Drive type | Electric |

|---|---|

| Load capacity (kg) | 3500 |

| Lifting height (mm) | 7780 |

| Driving speed with/without load | 20 / 20 km/h |