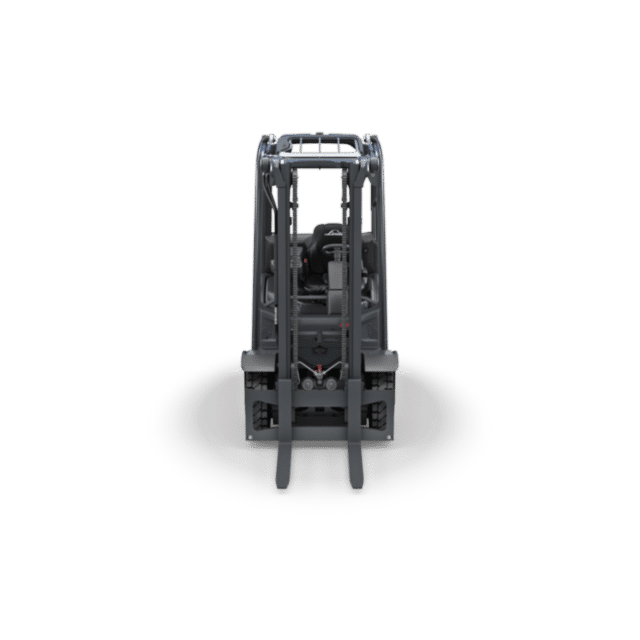

V-truck Linde H20 - H35

3500 kg

7780 mm

Diesel, propellant gas

Are you interested in this product?

Product description

The V-Stacker H20 - H35 is powerful, user-friendly, robust, low-maintenance and versatile. The truck for loads between 2,000 and 3,500 kilograms is particularly suitable for high loads in multi-shift operation and operations under the toughest external conditions. Hydrostatic drive, dual pedal control, Linde Load Control and optimum visibility ensure precise interaction between machine and operator. Design details together with intelligent assistance systems ensure the highest possible level of safety. Wireless data transmission allows the H20 - H35 to be integrated into software systems, e.g. for fleet management. The vehicle complies with the latest exhaust emission level EU 5 (2016/1627) and once again drastically undercuts the legally required emissions.

Features

Slim, asymmetrical mast profiles, narrow A-pillar, spacious and bright driver's compartment and the lowered front plate ensure excellent visibility. The roof is equipped with particularly narrow cross struts or an optional armored glass roof to ensure good upward visibility. The low vehicle center of gravity with high deflection steering axle ensures tilt resistance in curves. As standard safety equipment, Linde Curve Assist provides support when cornering, while Linde Load Assist reduces the risk of tipping and loading accidents. In addition, the vehicles can be equipped with the LED Stripes, Linde VertiLight, Linde TruckSpot and Linde BlueSpot™ light and warning solutions, as well as the Linde Safety Pilot and Linde Safety Guard assistance systems.

- Excellent visibility of load and surroundings

- Linde Curve Assist reduces speed when cornering

- Safe lifting of loads thanks to Linde Load Assist

- Numerous optional light and warning solutions

The H20 - H35 offers an ergonomic and intuitively organized operating concept; the steering wheel, dual pedals and the control levers of the Linde Load Control integrated in the armrest can be operated with a minimum of movement. To prevent shocks and vibrations from being transmitted to the driver, the drive and steering axles as well as the mast are decoupled from the frame and chassis by rubber mounts. A wide range of ergonomic seats actively protects against posture problems. Features such as air suspension, lumbar support, seat heating or seat ventilation provide additional comfort. The 3.5-inch display provides the driver with important information about the vehicle at a glance.

- Intuitive operating concept for fatigue-free work

- Decoupled driver workstation protects against vibrations

- Maximum comfort due to many seat variants

- Standard 3.5-inch display

The interaction of hydrostatic drive, industrial engine, operating concept, ergonomic design and optimized all-round visibility ensures productive load handling. Dual pedal control and the control levers of the Linde Load Control ensure precise control of all travel and mast movements. In addition, frequently used functions can be optionally interconnected via freely assignable buttons in the armrest. The design of the mast profiles and overhead tilt cylinders ensures torsional stability and high residual capacities at high lift heights. Linde hydrostat and industrial engine minimize fuel consumption and maintenance, which increases availability and reduces operating costs.

- Precise control of hydraulic functions via Linde Load Control

- Double pedal control for fast reversing

- High residual capacities thanks to overhead tilt cylinders

- Individually assignable multifunction keys as an option

The robust design of the H20 - H35 as well as wear- and maintenance-free components such as the hydrostatic drive system or the lubrication-free tilt cylinders ensure high operational availability. Hydraulic oil intake filter and coolant pump do not need to be replaced, the hydraulic oil only needs to be changed after 6000 operating hours. The powerful and robust industrial engine has maintenance-free spur gears, eliminating the need to change timing belts as with automotive engines. Additional protection against damage is provided by the Engine Protection System (EPS) and, especially in extreme outside temperatures, by the Truck Health Monitoring sensors. Due to the transverse installation of the engine, the service openings are particularly generous and maintenance-relevant components are easily accessible and easy to replace.

- Robust vehicle construction

- Long maintenance intervals due to wear-free components

- Hydraulic oil change after 6000 operating hours

- Engine Protection System (EPS) protects against engine damage

- Easy maintenance thanks to generous service flaps

Model overview

Model | Load capacity / load | Load center distance | Wheelbase | Working aisle width for pallet 800 x 1200 lengthwise | Driving speed with / without load |

|---|---|---|---|---|---|

H20/600CNG | 2,0 (t) | 600 (mm) | 1865 (mm) | 4189 (mm) | 22 / 22 km/h |

H20/600CNG Container | 2,0 (t) | 600 (mm) | 1865 (mm) | 4189 (mm) | 22 / 22 km/h

|

H20/600D | 2,0 (t) | 600 (mm) | 1865 (mm) | 4189 (mm) | 22 / 22 km/h

|

H20/600D Container | 2,0 (t) | 600 (mm) | 1865 (mm) | 4189 (mm) | 22 / 22 km/h

|

H20/600T | 2,0 (t) | 600 (mm) | 1865 (mm) | 4189 (mm) | 22 / 22 km/h

|

H20/600T Container | 2,0 (t) | 600 (mm) | 1865 (mm) | 4189 (mm) | 22 / 22 km/h

|

H25/600CNG | 2,5 (t) | 600 (mm) | 1905 (mm) | 4271 (mm) | 22 / 22 km/h

|

H25/600CNG Container | 2,5 (t) | 600 (mm) | 1905 (mm) | 4271 (mm) | 22 / 22 km/h

|

H25/600CNG Beverages | 2,5 (t) | 600 (mm) | 1905 (mm) | 4271 (mm) | 22 / 22 km/h

|

H25/600D | 2,5 (t) | 600 (mm) | 1905 (mm) | 4271 (mm) | 22 / 22 km/h

|

H25/600D Container | 2,5 (t) | 600 (mm) | 1905 (mm) | 4271 (mm) | 22 / 22 km/h

|

H25/600D Beverages | 2,5 (t) | 600 (mm) | 1905 (mm) | 4271 (mm) | 22 / 22 km/h

|

H25/600T | 2,5 (t) | 600 (mm) | 1905 (mm) | 4271 (mm) | 22 / 22 km/h

|

H25/600T Container | 2,5 (t) | 600 (mm) | 1905 (mm) | 4271 (mm) | 22 / 22 km/h

|

H25/600T Beverages | 2,5 (t) | 600 (mm) | 1905 (mm) | 4271 (mm) | 22 / 22 km/h

|

H25CNG | 2,5 (t) | 500 (mm) | 1905 (mm) | 4231 (mm) | 22 / 22 km/h

|

H25CNG Container | 2,5 (t) | 500 (mm) | 1905 (mm) | 4231 (mm) | 22 / 22 km/h

|

H25D | 2,5 (t) | 500 (mm) | 1905 (mm) | 4231 (mm) | 22 / 22 km/h

|

H25D Container | 2,5 (t) | 500 (mm) | 1905 (mm) | 4231 (mm) | 22 / 22 km/h

|

H25T | 2,5 (t) | 500 (mm) | 1905 (mm) | 4231 (mm) | 22 / 22 km/h

|

H25T Container | 2,5 (t) | 500 (mm) | 1905 (mm) | 4231 (mm) | 22 / 22 km/h

|

H30CNG | 3,0 (t) | 500 (mm) | 1930 (mm) | 4290 (mm) | 22 / 22 km/h

|

H30CNG Container | 3,0 (t) | 500 (mm) | 1930 (mm) | 4290 (mm) | 22 / 22 km/h

|

H30CNG Beverages | 3,0 (t) | 500 (mm) | 1930 (mm) | 4290 (mm) | 22 / 22 km/h

|

H30D | 3,0 (t) | 500 (mm) | 1930 (mm) | 4290 (mm) | 22 / 22 km/h

|

H30D Container | 3,0 (t) | 500 (mm) | 1930 (mm) | 4290 (mm) | 22 / 22 km/h

|

H30D Beverages | 3,0 (t) | 500 (mm) | 1930 (mm) | 4290 (mm) | 22 / 22 km/h

|

H30T | 3,0 (t) | 500 (mm) | 1930 (mm) | 4290 (mm) | 22 / 22 km/h

|

H30T Container | 3,0 (t) | 500 (mm) | 1930 (mm) | 4290 (mm) | 22 / 22 km/h

|

H30T Drinks | 3,0 (t) | 500 (mm) | 1930 (mm) | 4290 (mm) | 22 / 22 km/h

|

H35CNG | 3,5 (t) | 500 (mm) | 1965 (mm) | 4332 (mm) | 22 / 22 km/h

|

H35CNG Container | 3,5 (t) | 500 (mm) | 1965 (mm) | 4332 (mm) | 22 / 22 km/h

|

H35CNG Beverages | 3,5 (t) | 500 (mm) | 1965 (mm) | 4332 (mm) | 22 / 22 km/h

|

H35D | 3,5 (t) | 500 (mm) | 1965 (mm) | 4332 (mm) | 22 / 22 km/h

|

H35D Container | 3,5 (t) | 500 (mm) | 1965 (mm) | 4332 (mm) | 22 / 22 km/h

|

H35D Beverages | 3,5 (t) | 500 (mm) | 1965 (mm) | 4332 (mm) | 22 / 22 km/h

|

H35T | 3,5 (t) | 500 (mm) | 1965 (mm) | 4332 (mm) | 22 / 22 km/h

|

H35T Container | 3,5 (t) | 500 (mm) | 1965 (mm) | 4332 (mm) | 22 / 22 km/h

|

H35T Beverages | 3,5 (t) | 500 (mm) | 1965 (mm) | 4332 (mm) | 22 / 22 km/h

|

Videos & Pictures

Special equipment

The innovative Linde Steer Control concept from Linde Material Handling replaces the classic steering wheel with a mini steering wheel or joystick and increases ergonomics, precision and safety.

Tipping accidents with the counterbalanced truck can be largely avoided with the use of the Safety Pilot from Linde Material Handling.

Illuminated warning systems such as Linde BlueSpot™ and Linde TruckSpot project colored light dots or warning signs onto the floor to warn pedestrians and other vehicles.

The innovative Safety Guard assistance system from Linde warns vehicle operators and pedestrians of acute danger in the immediate vicinity of the vehicle by means of sounds and light signals.

The comfort cab protects the operator during outdoor operations and offers excellent all-round visibility of the load and working environment with an armored glass roof and large glass doors.

A wide range of seats provide additional comfort and active protection against posture problems with features such as air suspension, lumbar support, seat heating or seat ventilation.

This optional function shows the operator the current load weight on the fork in the display.

The powerful air conditioning system with integrated heating and pollen filter ensures a pleasant working climate in the cab in summer and winter and prevents fogged windows.

* Contains fluorinated hydrocarbons

The stacker is only 2,220 millimeters high, but still offers the operator an ergonomic workplace with plenty of headroom. Many container terminals and other halls with low clearance heights rely on these dimensions.

The two-color light strips of the Linde LED Stripes illuminate the respective driving direction of the truck with white light. With its semicircular design, the Linde VertiLight illuminates the work area over a large area.

The Linde Speed Assist driving assistance system automatically adjusts the vehicle's top speed to the surroundings and the driving situation.

In addition to the vehicle information, the 7-inch display can show, for example, the display for the Linde Safety Pilot or the image from mast or rear view cameras. The screen layout and displays can be customized.

Linde's connect fleet management system is used to manage the vehicle fleet. From maintenance planning and documentation of maintenance and repair history to access control.

Features

Slim, asymmetrical mast profiles, narrow A-pillar, spacious and bright driver's compartment and the lowered front plate ensure excellent visibility. The roof is equipped with particularly narrow cross struts or an optional armored glass roof to ensure good upward visibility. The low vehicle center of gravity with high deflection steering axle ensures tilt resistance in curves. As standard safety equipment, Linde Curve Assist provides support when cornering, while Linde Load Assist reduces the risk of tipping and loading accidents. In addition, the vehicles can be equipped with the LED Stripes, Linde VertiLight, Linde TruckSpot and Linde BlueSpot™ light and warning solutions, as well as the Linde Safety Pilot and Linde Safety Guard assistance systems.

- Excellent visibility of load and surroundings

- Linde Curve Assist reduces speed when cornering

- Safe lifting of loads thanks to Linde Load Assist

- Numerous optional light and warning solutions

The H20 - H35 offers an ergonomic and intuitively organized operating concept; the steering wheel, dual pedals and the control levers of the Linde Load Control integrated in the armrest can be operated with a minimum of movement. To prevent shocks and vibrations from being transmitted to the driver, the drive and steering axles as well as the mast are decoupled from the frame and chassis by rubber mounts. A wide range of ergonomic seats actively protects against posture problems. Features such as air suspension, lumbar support, seat heating or seat ventilation provide additional comfort. The 3.5-inch display provides the driver with important information about the vehicle at a glance.

- Intuitive operating concept for fatigue-free work

- Decoupled driver workstation protects against vibrations

- Maximum comfort due to many seat variants

- Standard 3.5-inch display

The interaction of hydrostatic drive, industrial engine, operating concept, ergonomic design and optimized all-round visibility ensures productive load handling. Dual pedal control and the control levers of the Linde Load Control ensure precise control of all travel and mast movements. In addition, frequently used functions can be optionally interconnected via freely assignable buttons in the armrest. The design of the mast profiles and overhead tilt cylinders ensures torsional stability and high residual capacities at high lift heights. Linde hydrostat and industrial engine minimize fuel consumption and maintenance, which increases availability and reduces operating costs.

- Precise control of hydraulic functions via Linde Load Control

- Double pedal control for fast reversing

- High residual capacities thanks to overhead tilt cylinders

- Individually assignable multifunction keys as an option

The robust design of the H20 - H35 as well as wear- and maintenance-free components such as the hydrostatic drive system or the lubrication-free tilt cylinders ensure high operational availability. Hydraulic oil intake filter and coolant pump do not need to be replaced, the hydraulic oil only needs to be changed after 6000 operating hours. The powerful and robust industrial engine has maintenance-free spur gears, eliminating the need to change timing belts as with automotive engines. Additional protection against damage is provided by the Engine Protection System (EPS) and, especially in extreme outside temperatures, by the Truck Health Monitoring sensors. Due to the transverse installation of the engine, the service openings are particularly generous and maintenance-relevant components are easily accessible and easy to replace.

- Robust vehicle construction

- Long maintenance intervals due to wear-free components

- Hydraulic oil change after 6000 operating hours

- Engine Protection System (EPS) protects against engine damage

- Easy maintenance thanks to generous service flaps

Technical data

- Designation: V-type forklift Linde H20 - H35

| Drive type | Diesel, propellant gas |

|---|---|

| Load capacity (kg) | 3500 |

| Lifting height (mm) | 7780 |

| Driving speed with/without load | 22 / 22 km/h |