V-type forklift Linde H35 - H50

5000 kg

7665 mm

Diesel, propellant gas

Are you interested in this product?

Product description

The reliable and robust V-type forklifts H35 - H50 for loads from 3,500 to 5,000 kilograms are designed for maximum handling performance. Their hydrostatic drive in combination with the powerful industrial engine ensures powerful and precisely controllable power development in a wide variety of driving and working situations. Neither extreme temperatures nor dusty, uneven floors affect these robust trucks. They are particularly suitable for intensive continuous operation and the toughest outdoor conditions, for example in recycling companies or construction material yards. Long service intervals and maintenance-free components ensure high availability. Thanks to dual pedal control and Linde Load Control, operation is particularly convenient and efficient. The combination of precise performance, robust design and efficient handling makes the V-Trucks H35 - H50 particularly productive and economical in operation.

Features

The design of the H35 - H50 with the slim, asymmetrical mast profiles, the narrow A-pillar, the spacious and bright cab and the lowered face plate ensures excellent all-round visibility, safe working and prevents fatigue. For good upward visibility, the roof is equipped with extra narrow crossbars or an optional armored glass roof. The low vehicle center of gravity and high-suspension steering axle ensure tilt resistance in curves. The standard Linde Curve Assist reduces the truck's speed when cornering depending on the steering angle. Linde Load Assist reduces the risk of tipping and loading accidents. In addition, the vehicles can be equipped with the LED Stripes, Linde VertiLight, Linde TruckSpot and Linde BlueSpot™ light and warning solutions, as well as the Linde Safety Pilot and Linde Safety Guard assistance systems.

- Excellent all-round visibility

- Low vehicle center of gravity

- Various safety assistance systems

- Optional light and warning solutions

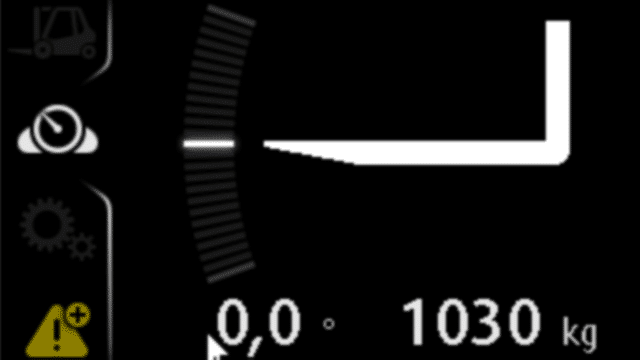

The H35 - H50 features an ergonomic and intuitively organized operating concept that increases the productivity of both man and machine. The steering wheel, dual pedals and the control levers of the Linde Load Control integrated into the armrest can be operated with a minimum of movement. This protects users from fatigue. The design and feel of all controls are on a par with automotive industry standards. The drive and steering axles and the mast are decoupled from the frame and chassis by rubber mounts. This prevents shocks and vibrations from being transmitted to the driver. Optional extras such as air suspension, lumbar support, seat heating or seat ventilation provide additional comfort. The 3.5-inch display provides the driver with important information about the vehicle at a glance. A 7-inch display integrated into the vehicle is optionally available and can be used for a mast or rear view camera, for example.

- Intuitive and ergonomic operating concept

- Decoupled driver workstation

- Many seat variants

- Standard 3.5-inch display

The interaction of the hydrostatic drive and the robust industrial engine provides exactly the power required in every work situation. This increases productivity and availability while minimizing fuel consumption, maintenance and operating costs. Combined with the ergonomic design and optimized all-round visibility, the Linde Load Control dual pedal steering and control levers enable precise and fast control of all travel and mast movements. The mast profiles and overhead tilt cylinders ensure torsional stability and high residual capacities at high lift heights. Frequently used functions can optionally be interconnected via freely assignable buttons in the armrest.

- Hydrostatic drive

- Linde Load Control

- Double pedal control

- Top tilt cylinder

- Multifunction keys as option

The H35 - H50 is characterized by a robust design and many maintenance-free components such as the hydrostatic drive system and the lubrication-free tilt cylinders. This ensures high operational availability at low operating costs. Hydraulic oil only needs to be changed after 6,000 hours of operation, and thanks to the maintenance-free spur gears of the industrial engine, there is no need to change the toothed belt commonly found in automotive engines. Additional protection against damage is provided by the Linde Engine Protection System (LEPS), which monitors important engine parameters. It warns of impending overload and limits the vehicle to creep speed. The service openings are particularly generous due to the transverse installation of the engine. This makes maintenance-relevant components very accessible and easy to replace. In addition, the largely standardized screw connections significantly reduce the time required for repair and maintenance work.

- Robust vehicle construction

- Wear-free components

- Hydraulic oil change after 6,000 operating hours

- Linde Engine Protection System (LEPS)

- Unified screw connections

Model overview*

Model | Load capacity / load | Load center distance | Wheelbase | Working aisle width for pallet 800 x 1200 lengthwise | Driving speed with / without load |

|---|---|---|---|---|---|

H35/600 CNG | 3,5 (t) | 600 (mm) | 2030 (mm) | 4643 (mm) | 21 / 21 km/h |

H35/600D | 3,5 (t) | 600 (mm) | 2030 (mm) | 4643 (mm) | 21 / 21 km/h |

H35/600D container | 3,5 (t) | 600 (mm) | 2030 (mm) | 4643 (mm) | 20 / 20 km/h |

H35/600D Beverages | 3,5 (t) | 600 (mm) | 2030 (mm) | 4643 (mm) | 21 / 21 km/h |

H35/600T | 3,5 (t) | 600 (mm) | 2030 (mm) | 4643 (mm) | 21 / 21 km/h |

H35/600T container | 3,5 (t) | 600 (mm) | 2030 (mm) | 4643 (mm) | 20 / 20 km/h |

H35/600T Beverages | 3,5 (t) | 600 (mm) | 2030 (mm) | 4643 (mm) | 21 / 21 km/h |

H40/600 CNG | 4,0 (t) | 600 (mm) | 2030 (mm) | 4653 (mm) | 21 / 21 km/h |

H40/600D | 4,0 (t) | 600 (mm) | 2030 (mm) | 4653 (mm) | 21 / 21 km/h |

H40/600D container | 4,0 (t) | 600 (mm) | 2030 (mm) | 4653 (mm) | 20 / 20 km/h |

H40/600D Beverages | 4,0 (t) | 600 (mm) | 2030 (mm) | 4653 (mm) | 21 / 21 km/h |

H40/600T | 4,0 (t) | 600 (mm) | 2030 (mm) | 4653 (mm) | 21 / 21 km/h |

H40/600T container | 4,0 (t) | 600 (mm) | 2030 (mm) | 4653 (mm) | 20 / 20 km/h |

H40/600T Beverages | 4,0 (t) | 600 (mm) | 2030 (mm) | 4653 (mm) | 21 / 21 km/h |

H45/600 CNG | 4,5 (t) | 600 (mm) | 2070 (mm) | 4720 (mm) | 24 / 24 km/h |

H45/600D | 4,5 (t) | 600 (mm) | 2070 (mm) | 4720 (mm) | 24 / 24 km/h |

H45/600D container | 4,5 (t) | 600 (mm) | 2070 (mm) | 4695 (mm) | 20 / 20 km/h |

H45/600D Beverages | 4,5 (t) | 600 (mm) | 2070 (mm) | 4720 (mm) | 24 / 24 km/h |

H45/600T | 4,5 (t) | 600 (mm) | 2070 (mm) | 4720 (mm) | 24 / 24 km/h |

H45/600T container | 4,5 (t) | 600 (mm) | 2070 (mm) | 4695 (mm) | 20 / 20 km/h |

H45/600T Beverages | 4,5 (t) | 600 (mm) | 2070 (mm) | 4720 (mm) | 24 / 24 km/h |

H50/500 CNG | 4,999 (t) | 500 (mm) | 2070 (mm) | 4720 (mm) | 24 / 24 km/h |

H50/500D | 4,999 (t) | 500 (mm) | 2070 (mm) | 4720 (mm) | 24 / 24 km/h |

H50/500D container | 4,999 (t) | 500 (mm) | 2070 (mm) | 4695 (mm) | 20 / 20 km/h |

H50/500T | 4,999 (t) | 500 (mm) | 2070 (mm) | 4720 (mm) | 24 / 24 km/h |

H50/500T container | 4,999 (t) | 500 (mm) | 2070 (mm) | 4695 (mm) | 20 / 20 km/h |

H50/600 CNG | 4,999 (t) | 600 (mm) | 2110 (mm) | 4763 (mm) | 24 / 24 km/h |

H50/600D | 4,999 (t) | 600 (mm) | 2110 (mm) | 4763 (mm) | 24 / 24 km/h |

H50/600D container | 4,999 (t) | 600 (mm) | 2110 (mm) | 4738 (mm) | 20 / 20 km/h |

H50/600D Beverages | 4,999 (t) | 600 (mm) | 2110 (mm) | 4763 (mm) | 24 / 24 km/h |

H50/600T | 4,999 (t) | 600 (mm) | 2110 (mm) | 4763 (mm) | 24 / 24 km/h |

H50/600T container | 4,999 (t) | 600 (mm) | 2110 (mm) | 4738 (mm) | 20 / 20 km/h |

H50/600T Beverages | 4,999 (t) | 600 (mm) | 2110 (mm) | 4763 (mm) | 24 / 24 km/h |

Special equipment

Tipping accidents with the counterbalanced truck can be largely avoided with the use of the Safety Pilot from Linde Material Handling.

Illuminated warning systems such as Linde TruckSpot and Linde BlueSpot™ project warning signs or colored light spots onto the floor to warn pedestrians and other vehicles.

The innovative Safety Guard assistance system from Linde warns vehicle operators and pedestrians of acute danger in the immediate vicinity of the vehicle by means of sounds and light signals.

The comfort cab protects the operator during outdoor operations and offers excellent all-round visibility of the load and working environment with an armored glass roof and large glass doors.

A wide range of seats provides additional comfort and active protection against posture problems with features such as air suspension, lumbar support, seat heating or seat ventilation.

This optional function shows the operator the current load weight on the fork in the display.

The powerful air conditioning system (contains fluorinated hydrocarbons) with integrated heating and pollen filter ensures a pleasant working climate in the cab in summer and winter and prevents fogged windows.

With its semicircular design, the Linde VertiLight illuminates the work area over a large area. The two-color light strips of the Linde LED Stripes illuminate the respective driving direction of the truck with white light.

The Linde Speed Assist driver assistance system automatically adjusts the truck's maximum speed to the surroundings and the driving situation.

In addition to the vehicle information, the 7-inch display can show, for example, the display for the Linde Safety Pilot or the image from mast or rear view cameras. The screen layout and displays can be customized.

Linde's connect fleet management system is used to manage the vehicle fleet. From maintenance planning and documentation of maintenance and repair history to access control.

Features

The design of the H35 - H50 with the slim, asymmetrical mast profiles, the narrow A-pillar, the spacious and bright cab and the lowered face plate ensures excellent all-round visibility, safe working and prevents fatigue. For good upward visibility, the roof is equipped with extra narrow crossbars or an optional armored glass roof. The low vehicle center of gravity and high-suspension steering axle ensure tilt resistance in curves. The standard Linde Curve Assist reduces the truck's speed when cornering depending on the steering angle. Linde Load Assist reduces the risk of tipping and loading accidents. In addition, the vehicles can be equipped with the LED Stripes, Linde VertiLight, Linde TruckSpot and Linde BlueSpot™ light and warning solutions, as well as the Linde Safety Pilot and Linde Safety Guard assistance systems.

- Excellent all-round visibility

- Low vehicle center of gravity

- Various safety assistance systems

- Optional light and warning solutions

The H35 - H50 features an ergonomic and intuitively organized operating concept that increases the productivity of both man and machine. The steering wheel, dual pedals and the control levers of the Linde Load Control integrated into the armrest can be operated with a minimum of movement. This protects users from fatigue. The design and feel of all controls are on a par with automotive industry standards. The drive and steering axles and the mast are decoupled from the frame and chassis by rubber mounts. This prevents shocks and vibrations from being transmitted to the driver. Optional extras such as air suspension, lumbar support, seat heating or seat ventilation provide additional comfort. The 3.5-inch display provides the driver with important information about the vehicle at a glance. A 7-inch display integrated into the vehicle is optionally available and can be used for a mast or rear view camera, for example.

- Intuitive and ergonomic operating concept

- Decoupled driver workstation

- Many seat variants

- Standard 3.5-inch display

The interaction of the hydrostatic drive and the robust industrial engine provides exactly the power required in every work situation. This increases productivity and availability while minimizing fuel consumption, maintenance and operating costs. Combined with the ergonomic design and optimized all-round visibility, the Linde Load Control dual pedal steering and control levers enable precise and fast control of all travel and mast movements. The mast profiles and overhead tilt cylinders ensure torsional stability and high residual capacities at high lift heights. Frequently used functions can optionally be interconnected via freely assignable buttons in the armrest.

- Hydrostatic drive

- Linde Load Control

- Double pedal control

- Top tilt cylinder

- Multifunction keys as option

The H35 - H50 is characterized by a robust design and many maintenance-free components such as the hydrostatic drive system and the lubrication-free tilt cylinders. This ensures high operational availability at low operating costs. Hydraulic oil only needs to be changed after 6,000 hours of operation, and thanks to the maintenance-free spur gears of the industrial engine, there is no need to change the toothed belt commonly found in automotive engines. Additional protection against damage is provided by the Linde Engine Protection System (LEPS), which monitors important engine parameters. It warns of impending overload and limits the vehicle to creep speed. The service openings are particularly generous due to the transverse installation of the engine. This makes maintenance-relevant components very accessible and easy to replace. In addition, the largely standardized screw connections significantly reduce the time required for repair and maintenance work.

- Robust vehicle construction

- Wear-free components

- Hydraulic oil change after 6,000 operating hours

- Linde Engine Protection System (LEPS)

- Unified screw connections

Technical data

- Designation: V-type forklift Linde H35 - H50

| Drive type | Diesel, propellant gas |

|---|---|

| Load capacity (kg) | 5000 |

| Lifting height (mm) | 7665 |

| Driving speed with/without load | 24 / 24 km/h |