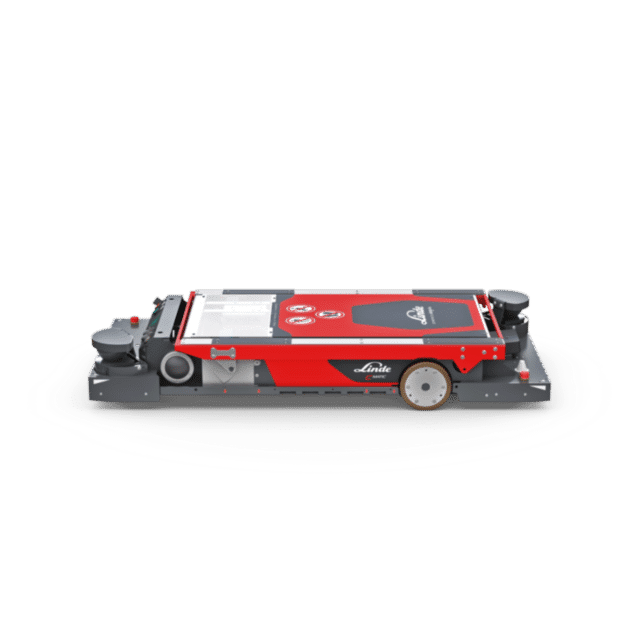

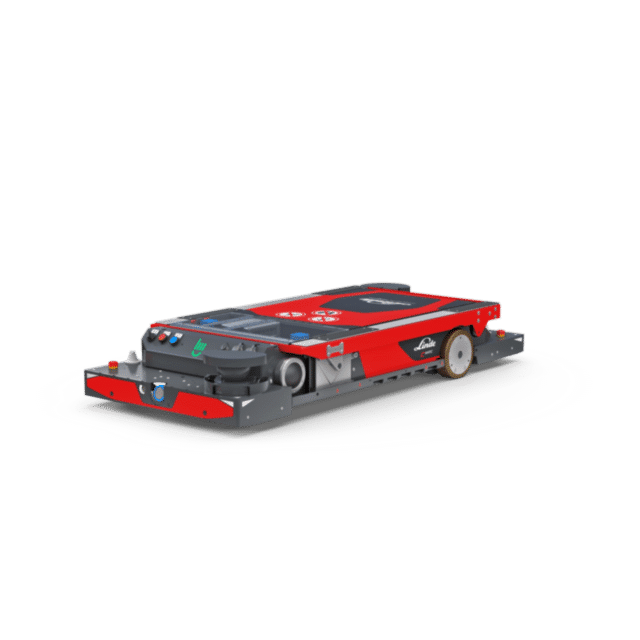

Automated vehicles Linde C-MATIC HP

1000 kg

40 mm

Electric

Are you interested in this product?

Product description

The Linde C-MATIC HP autonomous mobile transport robot is the ideal solution for automated processes in mixed operations, where it can easily operate together with people, manual vehicles and other autonomous industrial trucks in the same environment. It autonomously transports pallets and rolling racks, moves loads weighing up to 1,000 kilograms over medium and long distances, and reaches a maximum speed of 8 km/h. Thanks to innovative contour navigation (SLAM), the vehicle searches for its own route and is therefore able to avoid obstacles if necessary. A permanently installed infrastructure is not necessary. The C-MATIC HP is optimized for flexible load handling. This means it can also pick up load carriers that are not ideally positioned, such as trolleys. The transport robot can be effortlessly integrated into the overall intralogistics processes via the cloud-based software control.

Features

Using laser scanners, the C-MATIC HP detects the complete vehicle environment and reacts immediately if people, vehicles or static obstacles block its path. Thanks to real-time data processing, it is able to avoid detected obstacles and independently search for an alternative route. The precise movements of the C-MATIC HP enable it to pick up loads stably when transporting pallets or rolling racks. For additional stability when handling pallets, it can be equipped with a precision-fit adapter plate. Emergency stop switches are located on both sides of the vehicle for easy access in case of incidents. All this makes the C-MATIC HP an optimal combination of flexibility, productivity and highest possible safety.

- Environment control by laser scanner

- Real time data processing

- Reliable protection of people and vehicles

- Stable load support

- Emergency stop switch on both sides

The C-MATIC HP orient themselves by means of laser-based contour navigation. A permanently installed infrastructure such as magnetic tapes or QR codes is not necessary. If the application area changes, they update their previous environment map. The C-MATIC HP actively avoid obstacles and independently search for alternative routes, which ensures a stable material flow. The transport robots are also suitable for partially automated processes in which they work in combination with manually operated industrial trucks. They can be easily integrated into existing processes via cloud-based control software. The flat overall height of the C-MATIC HP makes it easier to drive underneath roller racks and pick up pallets at transfer stations. In doing so, they can also pick up loads that have not been optimally positioned for pickup. Optional adapter plates are available for direct pallet transport. A lithium-ion battery and self-charging when the battery is low makes them ideal for 24/7 operation.

- Infrastructure-free SLAM navigation

- Actively driving around obstacles

- Optimal for use in mixed operation

- Flexible load handling

- Effortless implementation

- Lithium-ion battery and self-charging function

The reliable technology and robust components of the C-MATIC HP guarantee low service requirements and keep maintenance and repair costs low. For fast maintenance, all relevant electronic and mechanical components are easily accessible, which additionally improves the availability of the vehicle. All vehicle data can be read out via a diagnostic cable connection using a service laptop and analyzed by diagnostic software. Alternatively, the vehicle can be monitored and adjusted via a computer-aided remote diagnosis function. Linde's worldwide service network is available at all times for repair and maintenance of the vehicle.

- Robust vehicle construction

- Long service intervals

- Easily accessible components

- Error analysis via laptop

- Monitoring through remote diagnostics function

Model overview

Model | Load capacity | Load dimensions b12 x l6 | Height lowered | Driving speed with/without load |

|---|---|---|---|---|

C-MATIC HP 10 | 1,0 (t) | 1260 x 860 (mm) | 222 (mm) | 8 km/h |

Special equipment

The C-MATIC HP can be optionally equipped with an adapter plate to perform direct pallet transport from transfer station to transfer station reliably and efficiently in mixed operation.

Features

Using laser scanners, the C-MATIC HP detects the complete vehicle environment and reacts immediately if people, vehicles or static obstacles block its path. Thanks to real-time data processing, it is able to avoid detected obstacles and independently search for an alternative route. The precise movements of the C-MATIC HP enable it to pick up loads stably when transporting pallets or rolling racks. For additional stability when handling pallets, it can be equipped with a precision-fit adapter plate. Emergency stop switches are located on both sides of the vehicle for easy access in case of incidents. All this makes the C-MATIC HP an optimal combination of flexibility, productivity and highest possible safety.

- Environment control by laser scanner

- Real time data processing

- Reliable protection of people and vehicles

- Stable load support

- Emergency stop switch on both sides

The C-MATIC HP orient themselves by means of laser-based contour navigation. A permanently installed infrastructure such as magnetic tapes or QR codes is not necessary. If the application area changes, they update their previous environment map. The C-MATIC HP actively avoid obstacles and independently search for alternative routes, which ensures a stable material flow. The transport robots are also suitable for partially automated processes in which they work in combination with manually operated industrial trucks. They can be easily integrated into existing processes via cloud-based control software. The flat overall height of the C-MATIC HP makes it easier to drive underneath roller racks and pick up pallets at transfer stations. In doing so, they can also pick up loads that have not been optimally positioned for pickup. Optional adapter plates are available for direct pallet transport. A lithium-ion battery and self-charging when the battery is low makes them ideal for 24/7 operation.

- Infrastructure-free SLAM navigation

- Actively driving around obstacles

- Optimal for use in mixed operation

- Flexible load handling

- Effortless implementation

- Lithium-ion battery and self-charging function

The reliable technology and robust components of the C-MATIC HP guarantee low service requirements and keep maintenance and repair costs low. For fast maintenance, all relevant electronic and mechanical components are easily accessible, which additionally improves the availability of the vehicle. All vehicle data can be read out via a diagnostic cable connection using a service laptop and analyzed by diagnostic software. Alternatively, the vehicle can be monitored and adjusted via a computer-aided remote diagnosis function. Linde's worldwide service network is available at all times for repair and maintenance of the vehicle.

- Robust vehicle construction

- Long service intervals

- Easily accessible components

- Error analysis via laptop

- Monitoring through remote diagnostics function

Technical data

- Name: Automated vehicles Linde C-MATIC HP

| Drive type | Electric |

|---|---|

| Load capacity (kg) | 1000 |

| Lifting height (mm) | 40 |

| Driving speed with/without load | 8 / 8 km/h |