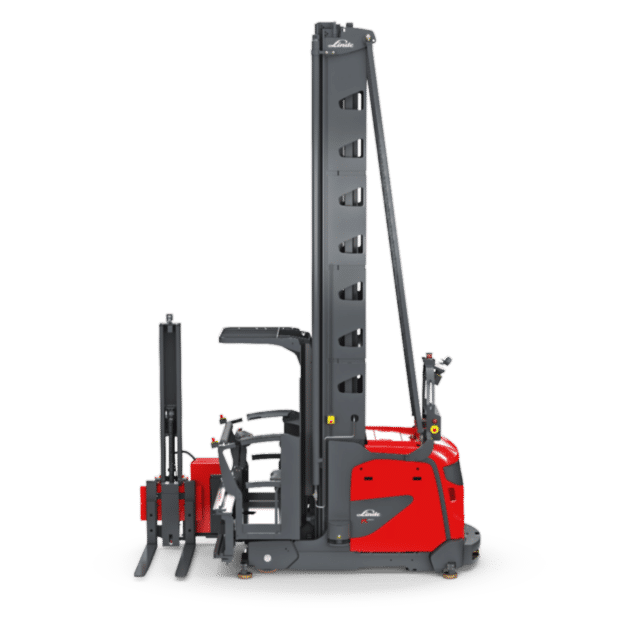

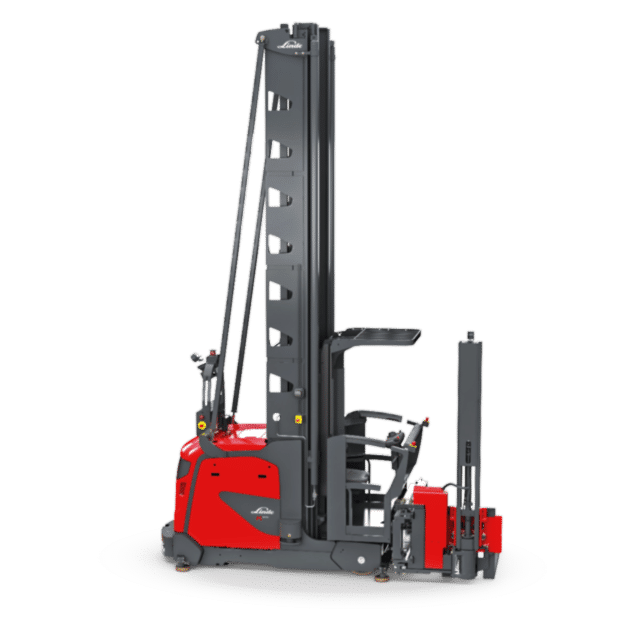

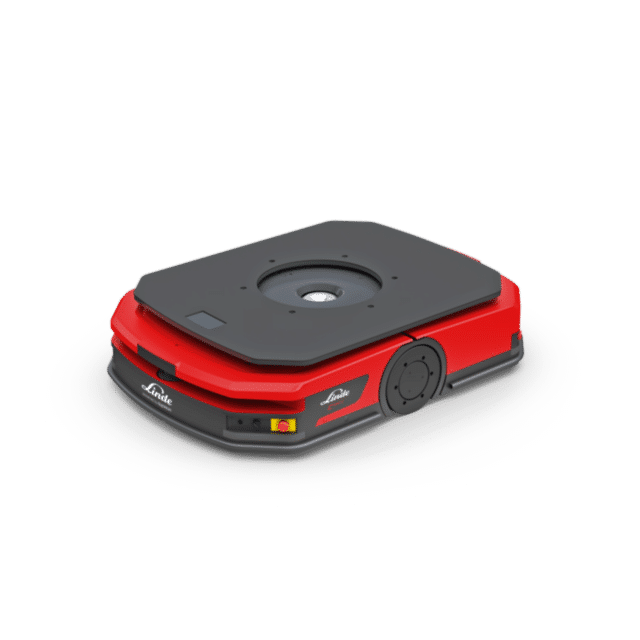

Automated vehicles Linde K-MATIC

1500 kg

12850 mm

Electric

Are you interested in this product?

Product description

Features

With its on-board safety system, the K-MATIC self-steering truck reacts sensitively to its surroundings. Thanks to its laser- and camera-based safety equipment, which is independent of the navigation technology, the K-MATIC steers safely through the operating environment and reliably detects people and other obstacles. The self-propelled narrow-aisle truck is also equipped with several emergency stop buttons as well as warning tones and flashing lights.

- All-round monitoring of the working environment

- Combined safety technology with lasers and cameras

- Audible and visual warning systems

The K-MATIC automated narrow aisle truck is controlled by the Supervisor software, which optimally coordinates the orders and routes of all MATIC vehicles in use. The system is compatible with common warehouse management and ERP systems and translates the required goods movements into driving orders. The 3D pallet recognition system with integrated distance monitoring ensures smooth storage and retrieval processes in the racking. In addition, the laser and camera-based safety system ensures that the narrow-aisle truck moves without losing much time, even in areas with normal operating traffic. For example, the monitored areas around the truck are adjusted in real time depending on travel speed and curves. If the truck stops because an obstacle has been detected, it automatically resumes the operation as soon as the way is clear again. Changes in the operational environment can be remapped in a short time by laser measurement and imported into the system.

- Interface to warehouse management and ERP systems

- Intelligent route and job control

- Precise control and monitoring of pallet movements

- Safe operation with people and non-autonomous vehicles

- Flexibly adaptable to changes

- Change to manual operation possible at any time

All essential vehicle and job data can be called up on the vehicle via a 7" LCD touch display and read out via USB. By entering a PIN, the technician activates the service mode and can safely perform the necessary maintenance work on the easily accessible components. Maintenance-relevant vehicle data is transmitted wirelessly and evaluated via diagnostic software. This enables predictive maintenance - wear and minor damage are detected at an early stage, and necessary inspection breaks and parts replacements are calculated and planned. This ensures maximum availability of the autonomous vehicle.

- Digital diagnostic tool

- Wireless transmission of vehicle data

- Predictive maintenance

Model overview

Model | Load capacity | Lifting height | Driving speed with/without load | Battery voltage / nominal capacity K5 |

|---|---|---|---|---|

K-MATIC example 0.7 | 0,7 (t) | 3200 (mm) | 10.5 / 10.5 km/h

| 80 / 465 (V)/(Ah) o. kWh |

K-MATIC Example 1.0 | 1,0 (t) | 7200 (mm) | 12 / 12 km/h

| 80 / 775 (V)/(Ah) o. kWh |

K-MATIC Example 1.5 | 1,5 (t) | 10800 (mm) | 12 / 12 km/h

| 80 / 930 (V)/(Ah) o. kWh |

Special equipment

Thanks to the powerful LED lights of the Linde BlueSpot™, employees are alerted to errant trucks in a pleasant but effective way: no loud noise, no startling, no risk.

Features

With its on-board safety system, the K-MATIC self-steering truck reacts sensitively to its surroundings. Thanks to its laser- and camera-based safety equipment, which is independent of the navigation technology, the K-MATIC steers safely through the operating environment and reliably detects people and other obstacles. The self-propelled narrow-aisle truck is also equipped with several emergency stop buttons as well as warning tones and flashing lights.

- All-round monitoring of the working environment

- Combined safety technology with lasers and cameras

- Audible and visual warning systems

The K-MATIC automated narrow aisle truck is controlled by the Supervisor software, which optimally coordinates the orders and routes of all MATIC vehicles in use. The system is compatible with common warehouse management and ERP systems and translates the required goods movements into driving orders. The 3D pallet recognition system with integrated distance monitoring ensures smooth storage and retrieval processes in the racking. In addition, the laser and camera-based safety system ensures that the narrow-aisle truck moves without losing much time, even in areas with normal operating traffic. For example, the monitored areas around the truck are adjusted in real time depending on travel speed and curves. If the truck stops because an obstacle has been detected, it automatically resumes the operation as soon as the way is clear again. Changes in the operational environment can be remapped in a short time by laser measurement and imported into the system.

- Interface to warehouse management and ERP systems

- Intelligent route and job control

- Precise control and monitoring of pallet movements

- Safe operation with people and non-autonomous vehicles

- Flexibly adaptable to changes

- Change to manual operation possible at any time

All essential vehicle and job data can be called up on the vehicle via a 7" LCD touch display and read out via USB. By entering a PIN, the technician activates the service mode and can safely perform the necessary maintenance work on the easily accessible components. Maintenance-relevant vehicle data is transmitted wirelessly and evaluated via diagnostic software. This enables predictive maintenance - wear and minor damage are detected at an early stage, and necessary inspection breaks and parts replacements are calculated and planned. This ensures maximum availability of the autonomous vehicle.

- Digital diagnostic tool

- Wireless transmission of vehicle data

- Predictive maintenance

Technical data

- Name: Automated vehicles Linde K-MATIC

| Drive type | Electric |

|---|---|

| Load capacity (kg) | 1500 |

| Lifting height (mm) | 12850 |

| Driving speed with/without load | 12 / 12 km/h |