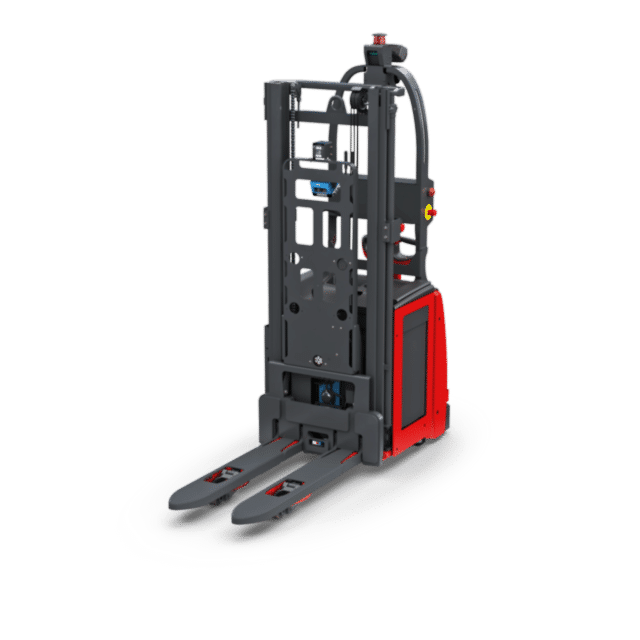

Automated vehicles Linde L-MATIC HD

2000 kg

4000 mm

Electric

Are you interested in this product?

Product description

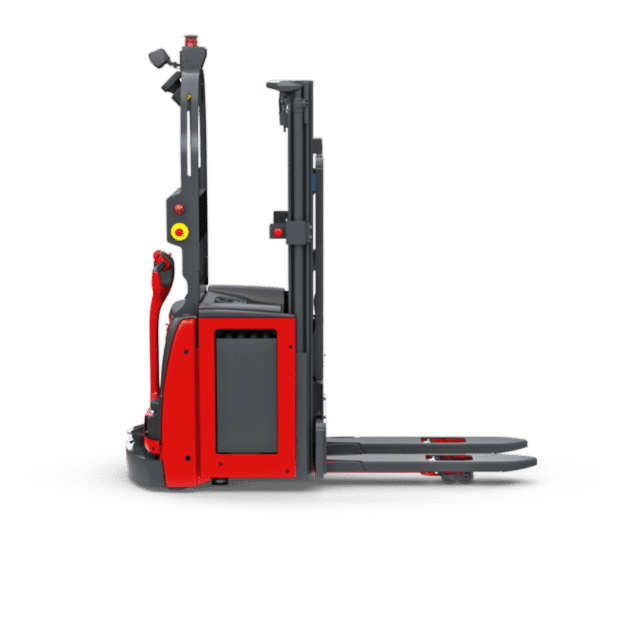

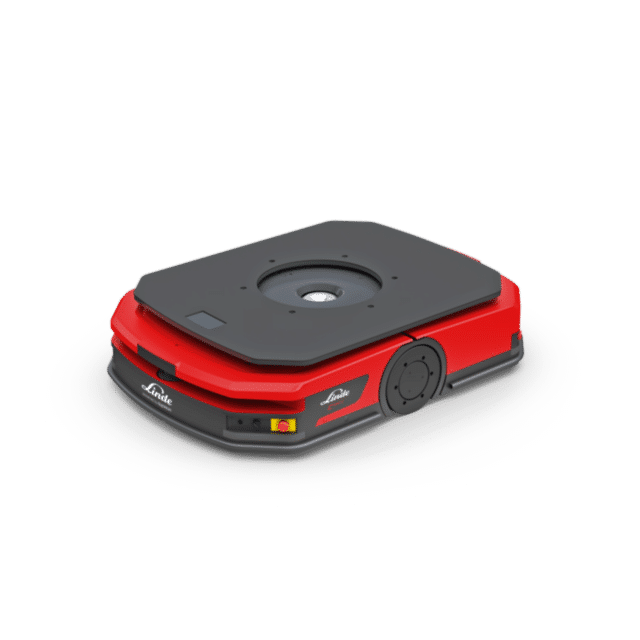

The L-MATIC HD is an automated high lift truck from Linde Material Handling. It is particularly well suited for applications in wide aisle warehouses with type 1 and 3 Euro pallets. The 1.6-ton model of the L-MATIC HD handles goods weighing up to 1,600 kilograms. For loads of up to 2,000 kilograms, the L-MATIC HD 2.0-ton model, which is specially built for the customer, is suitable. Both vehicle variants transport and store goods at lifting heights of up to 4 meters. The interaction of powerful hardware and intelligent software offers significant performance advantages. In particular, the 3D camera software, which was developed specifically for Linde, guarantees unique recognition of loads and surroundings. Among other things, it makes it possible to significantly shorten pick-and-drop cycles. In addition, users can use the L-MATIC HD in conjunction with narrow aisle applications. Integration into existing intralogistics solutions is straightforward thanks to intelligent contour navigation (SLAM), which requires no additional infrastructure. Thanks to an optional connection of automated loading stations, the L-MATIC HD is particularly suitable for implementing solutions with continuous operation (24/7). The comprehensive safety concept ensures reliable protection of operators, loads, vehicles and the environment.

Features

The Linde L-MATIC HD has comprehensive, sensor-based safety equipment. Laser scanners at the front and rear, and optionally at the side, monitor the entire working environment. As soon as the L-MATIC HD detects people, other vehicles or obstacles, it adjusts its speed or stops. In addition, people who are in the vehicle's safety zone are warned acoustically and visually. An additionally available 2D curtain laser enables the vehicle to also detect objects at height, such as overhanging loads or falling objects.

- All-round monitoring of the working environment

- Passive and active protection systems

- Intelligent, sensor-based safety equipment with lasers and cameras

- Automatic speed adaptation and collision avoidance

- Audible and visual warning systems

The L-MATIC HD is designed for the easiest possible operation and smooth integration into modern intralogistics environments. Operator inputs are made via a touchscreen with an intuitive user interface. The control software handles route guidance, order assignment, and energy management, and can be quickly connected to enterprise resource planning or ERP systems. Intelligent load detection with sensors for pallet recognition ensures safe handling even with maximum utilization of the load capacity. Linde's innovative, infrastructure-free contour navigation (SLAM) makes it possible to integrate all MATIC vehicles into existing work environments within a short time and adapt them to changing tasks. Smooth switching between manual and automated operation is possible via the intuitive tiller.

- Touchscreen with simple user interface

- Load detection for safe handling

- Intelligent route and job control

- Interface to warehouse management and ERP systems

- Precise control and monitoring of pallet movements

- Change to manual operation possible at any time

Efficiency in service also makes a decisive contribution to the efficiency in operation of the Linde L-MATIC HD. The automated high-lift truck is designed for applications in continuous operation. The electronic diagnostic system, in conjunction with predictive maintenance software, guarantees users maximum availability. All electronic and mechanical components are easily accessible. The drive and the optional modern energy system based on lithium-ion batteries are durable and largely maintenance-free.

- Digital diagnostic tool

- Predictive maintenance

- Maintenance-free power and drive system

Videos & Pictures

Special equipment

Thanks to the powerful LED lights of the Linde BlueSpot™, employees are alerted to errant automated vehicles in a pleasant but effective way: no loud noise, no startling, no risk.

Features

The Linde L-MATIC HD has comprehensive, sensor-based safety equipment. Laser scanners at the front and rear, and optionally at the side, monitor the entire working environment. As soon as the L-MATIC HD detects people, other vehicles or obstacles, it adjusts its speed or stops. In addition, people who are in the vehicle's safety zone are warned acoustically and visually. An additionally available 2D curtain laser enables the vehicle to also detect objects at height, such as overhanging loads or falling objects.

- All-round monitoring of the working environment

- Passive and active protection systems

- Intelligent, sensor-based safety equipment with lasers and cameras

- Automatic speed adaptation and collision avoidance

- Audible and visual warning systems

The L-MATIC HD is designed for the easiest possible operation and smooth integration into modern intralogistics environments. Operator inputs are made via a touchscreen with an intuitive user interface. The control software handles route guidance, order assignment, and energy management, and can be quickly connected to enterprise resource planning or ERP systems. Intelligent load detection with sensors for pallet recognition ensures safe handling even with maximum utilization of the load capacity. Linde's innovative, infrastructure-free contour navigation (SLAM) makes it possible to integrate all MATIC vehicles into existing work environments within a short time and adapt them to changing tasks. Smooth switching between manual and automated operation is possible via the intuitive tiller.

- Touchscreen with simple user interface

- Load detection for safe handling

- Intelligent route and job control

- Interface to warehouse management and ERP systems

- Precise control and monitoring of pallet movements

- Change to manual operation possible at any time

Efficiency in service also makes a decisive contribution to the efficiency in operation of the Linde L-MATIC HD. The automated high-lift truck is designed for applications in continuous operation. The electronic diagnostic system, in conjunction with predictive maintenance software, guarantees users maximum availability. All electronic and mechanical components are easily accessible. The drive and the optional modern energy system based on lithium-ion batteries are durable and largely maintenance-free.

- Digital diagnostic tool

- Predictive maintenance

- Maintenance-free power and drive system

Technical data

- Name: Automated vehicles Linde L-MATIC HD

| Drive type | Electric |

|---|---|

| Load capacity (kg) | 2000 |

| Lifting height (mm) | 4000 |