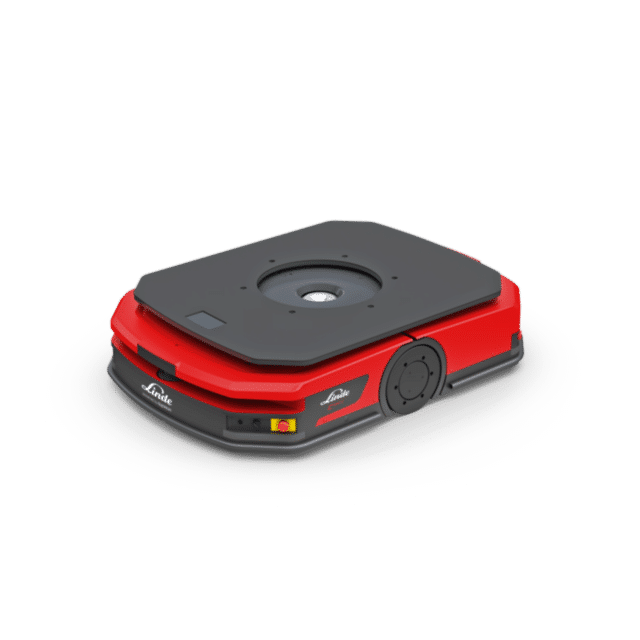

Automated vehicles Linde C-MATIC

1500 kg

60 mm

Electric

Are you interested in this product?

Product description

Features

Using the laser scanner, the C-MATIC reliably detects its surroundings and reacts immediately if people, vehicles or other obstacles block the travel path. It does not matter whether the obstacles are moving or stationary. Thanks to real-time information processing, the C-MATIC adjusts its speed to the respective situation or stops until the person and vehicles have left the monitoring zone. It thus ensures the ideal combination of maximum productivity and the highest possible safety. For additional protection, especially when turning on the spot and reversing, the C-MATIC is equipped with a stable collision guard all around. It also has separate emergency stop switches on all four sides.

- Laser scanner for environmental control

- Real time data processing

- Reliable protection of people and vehicles

- Emergency stop switch on all four sides

- Robust collision protection around the vehicle

The C-MATIC navigates on the basis of QR codes that are affixed to the hall floor at intervals of approximately one meter along the travel routes. The QR codes have a unique identifier and are stored as orientation points on a digital map. The software calculates the optimal route for each transport job. The optionally available transport tables are also equipped with QR codes. This enables the identification of the goods to be transported, the assignment of storage and set-down locations, and the alignment of the load carrier, e.g. to set down material at machines as required. Optionally, the software also monitors and controls the automated charging of the batteries with a self-charging station: If the charge level falls below a defined level, or if a device is not currently being used, the C-MATIC moves to the charging station and is available again once it has been fully charged or if there is an acute need.

- Navigation via QR codes

- Cargo tracking with QR codes on the transport tables

- Optimal route guidance and assignment of driving jobs

- Optional fully automated charging of the batteries

The robust technology of the C-MATIC enables long maintenance intervals and ensures low service and life cycle costs. The most important electronic and mechanical components are easily accessible for rapid maintenance. This design-to-service principle also contributes to the high availability of the vehicle. All vehicle data can be read out via cable connection.

- Robust vehicle construction

- Long maintenance intervals

- Easily accessible main components

- Error analysis via cable connection to laptop

Model overview

Model | Load capacity | Load dimensions b12 x l6 | Height lowered | Driving speed with/without load |

|---|---|---|---|---|

C-MATIC 06 | 0,6 (t) | 900×900 // (780 x 780) (mm) | 240 (mm) | 5.4 / 7.2 km/h

|

C-MATIC 10 | 1,0 (t) | 1200×1200 // (1080 x 1080) (mm) | 260 (mm) | 4.3 / 5.4 km/h

|

C-MATIC 15 | 1,5 (t) | 1200×1200 // (1080 x 1080) (mm) | 260 (mm) | 4.3 / 5.4 km/h

|

Special equipment

The adapter plate for direct pallet transport is available for the C-MATIC with 1,000 and 1,500 kilogram load capacities. It is ideal for transfer heights between 320 and 730 millimeters.

The under-ride transport tables enable standardized and flexible load handling. Via a QR code on the underside of the tables, the transported load can be precisely tracked and efficiently managed. Goods with and without pallets can be transported on the tables.

When the battery level is low, the C-MATIC independently searches for the charging station and carries out the charging process fully automatically. The charging time for a full charge is 1.5 hours. Several C-MATIC of the same type can be charged with one charging station.

Features

Using the laser scanner, the C-MATIC reliably detects its surroundings and reacts immediately if people, vehicles or other obstacles block the travel path. It does not matter whether the obstacles are moving or stationary. Thanks to real-time information processing, the C-MATIC adjusts its speed to the respective situation or stops until the person and vehicles have left the monitoring zone. It thus ensures the ideal combination of maximum productivity and the highest possible safety. For additional protection, especially when turning on the spot and reversing, the C-MATIC is equipped with a stable collision guard all around. It also has separate emergency stop switches on all four sides.

- Laser scanner for environmental control

- Real time data processing

- Reliable protection of people and vehicles

- Emergency stop switch on all four sides

- Robust collision protection around the vehicle

The C-MATIC navigates on the basis of QR codes that are affixed to the hall floor at intervals of approximately one meter along the travel routes. The QR codes have a unique identifier and are stored as orientation points on a digital map. The software calculates the optimal route for each transport job. The optionally available transport tables are also equipped with QR codes. This enables the identification of the goods to be transported, the assignment of storage and set-down locations, and the alignment of the load carrier, e.g. to set down material at machines as required. Optionally, the software also monitors and controls the automated charging of the batteries with a self-charging station: If the charge level falls below a defined level, or if a device is not currently being used, the C-MATIC moves to the charging station and is available again once it has been fully charged or if there is an acute need.

- Navigation via QR codes

- Cargo tracking with QR codes on the transport tables

- Optimal route guidance and assignment of driving jobs

- Optional fully automated charging of the batteries

The robust technology of the C-MATIC enables long maintenance intervals and ensures low service and life cycle costs. The most important electronic and mechanical components are easily accessible for rapid maintenance. This design-to-service principle also contributes to the high availability of the vehicle. All vehicle data can be read out via cable connection.

- Robust vehicle construction

- Long maintenance intervals

- Easily accessible main components

- Error analysis via cable connection to laptop

Technical data

- Name: Automated vehicles Linde C-MATIC

| Drive type | Electric |

|---|---|

| Load capacity (kg) | 1500 |

| Lifting height (mm) | 60 |

| Driving speed with/without load | 5.4 / 7.2 km/h |