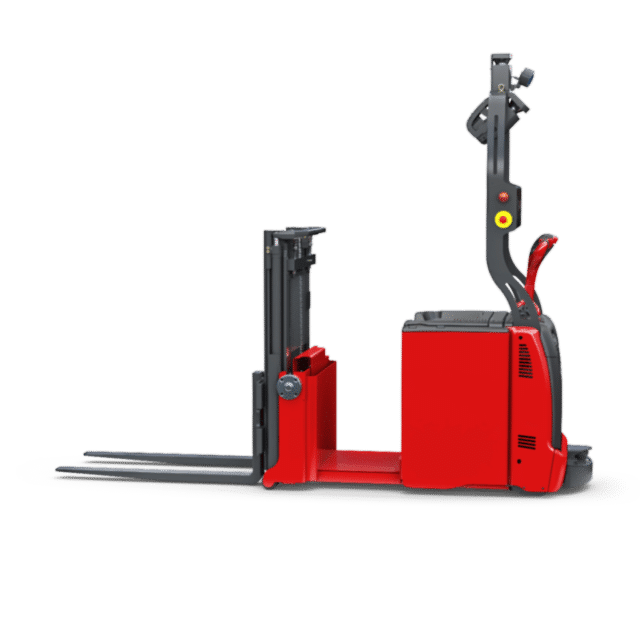

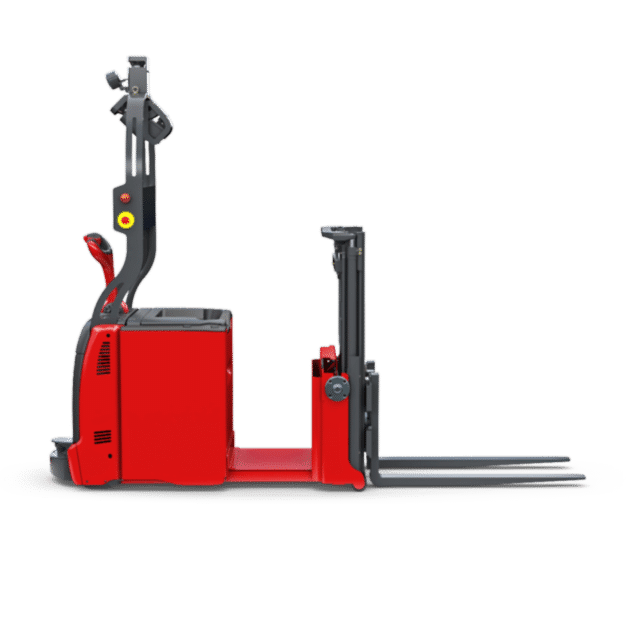

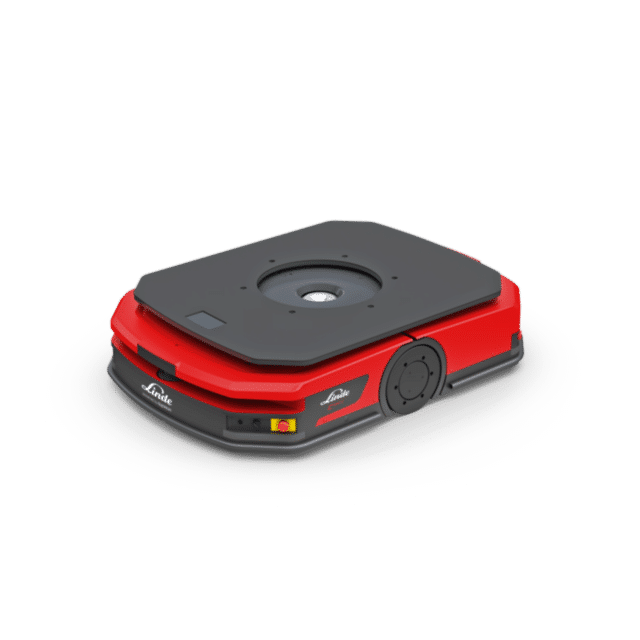

Automated vehicles Linde L-MATIC AC

1600 kg

1924 mm

Electric

Are you interested in this product?

Product description

The Linde L-MATIC AC autonomous high lift truck with cantilever forks simplifies the transport of closed load carriers and the picking up of goods at transfer stations that cannot be driven under with wheel arms, such as on roller conveyors. The counterbalance vehicle, which can also be operated manually at any time, handles loads of up to 1,200 kilograms and lifting heights of 1.90 meters. It can be used on its own or integrated into an automated fleet. The intelligent contour navigation system (SLAM) does not require additional conductive tracks in the floor or laser reflectors. The L-MATIC AC can therefore be used flexibly in different or changing operating environments. Its comprehensive safety features reliably detect obstacles and people in the operating environment.

Features

Thanks to its camera- and laser-based safety equipment, the Linde L-MATIC AC monitors its working environment and reacts independently to obstacles and people. If an obstacle is detected, the vehicle reduces speed and only stops if the obstacle does not move any further. This function ensures high safety and high productivity at the same time. The L-MATIC AC can be stopped at any time via emergency stop switches located in several places. Warning sounds and flashing lights complete the safety concept of the robotic vehicle. To move the machine out of a danger zone in an emergency, it can be moved manually at any time using the tiller.

- Anticipatory safety system

- Safe collision avoidance

- Acoustic-visual warning systems

The autonomous high-lift truck interacts with other automated equipment, such as hall doors or transport roller conveyors, and can be used as part of a fleet or individually for the automation of repetitive work processes. Route guidance and job assignment are controlled by the supervisor software. The system can be used to initiate transport orders directly from the merchandise management or ERP system. The innovative account navigation (SLAM) enables MATIC vehicles to be deployed in a changed or new work environment within a short time. Thanks to advanced safety technology, the L-MATIC AC anticipates obstacles and resumes the work process independently when people or other vehicles are no longer in the monitoring zone. In mixed work processes, the vehicle works toward people without any safety restrictions.

- Interface to warehouse management and ERP systems

- Intelligent route and job control

- Precise control and monitoring of pallet movements

- Safe operation with people and non-autonomous vehicles

- Flexibly adaptable to changes

- Change to manual operation possible at any time

Thanks to the specially developed networking of the vehicle's control units, all data from the L-MATIC AC can be read out on a service laptop. However, the high-lift truck can also be monitored via a remote diagnostic system. The vehicle offers high availability, as all electronic and mechanical components are easily accessible and the drives operate with maintenance-free three-phase AC technology. The operational readiness of the L-MATIC AC is thus guaranteed for a long time.

- Digital diagnostic tool

- Remote inspection

- Predictive maintenance

- Maintenance-free three-phase technology

Model overview

Model | Load capacity | Lifting height | Driving speed with/without load | Battery voltage / nominal capacity K5 |

|---|---|---|---|---|

L-MATIC AC 1.2 | 1,2 (t) | 1924 (mm) | 6/6 (max. 7.2/2.9) km/h

| 24 / 345/375 (V)/(Ah) o. kWh |

L-MATIC AC 1.6 | 1,6 (t) | 1844 (mm) | 6/6 (max. 7.2/2.9) km/h

| 24 / 460/500 (V)/(Ah) o. kWh |

Special equipment

The Linde BlueSpot™ driveway warning system increases safety during operation, as the LED spotlight makes trucks silently visible.

The L-MATIC AC can be optionally equipped with an additional horn. This makes the high-lift truck more audible in particularly noisy environments.

Features

Thanks to its camera- and laser-based safety equipment, the Linde L-MATIC AC monitors its working environment and reacts independently to obstacles and people. If an obstacle is detected, the vehicle reduces speed and only stops if the obstacle does not move any further. This function ensures high safety and high productivity at the same time. The L-MATIC AC can be stopped at any time via emergency stop switches located in several places. Warning sounds and flashing lights complete the safety concept of the robotic vehicle. To move the machine out of a danger zone in an emergency, it can be moved manually at any time using the tiller.

- Anticipatory safety system

- Safe collision avoidance

- Acoustic-visual warning systems

The autonomous high-lift truck interacts with other automated equipment, such as hall doors or transport roller conveyors, and can be used as part of a fleet or individually for the automation of repetitive work processes. Route guidance and job assignment are controlled by the supervisor software. The system can be used to initiate transport orders directly from the merchandise management or ERP system. The innovative account navigation (SLAM) enables MATIC vehicles to be deployed in a changed or new work environment within a short time. Thanks to advanced safety technology, the L-MATIC AC anticipates obstacles and resumes the work process independently when people or other vehicles are no longer in the monitoring zone. In mixed work processes, the vehicle works toward people without any safety restrictions.

- Interface to warehouse management and ERP systems

- Intelligent route and job control

- Precise control and monitoring of pallet movements

- Safe operation with people and non-autonomous vehicles

- Flexibly adaptable to changes

- Change to manual operation possible at any time

Thanks to the specially developed networking of the vehicle's control units, all data from the L-MATIC AC can be read out on a service laptop. However, the high-lift truck can also be monitored via a remote diagnostic system. The vehicle offers high availability, as all electronic and mechanical components are easily accessible and the drives operate with maintenance-free three-phase AC technology. The operational readiness of the L-MATIC AC is thus guaranteed for a long time.

- Digital diagnostic tool

- Remote inspection

- Predictive maintenance

- Maintenance-free three-phase technology

Technical data

- Name: Automated vehicles Linde L-MATIC AC

| Drive type | Electric |

|---|---|

| Load capacity (kg) | 1600 |

| Lifting height (mm) | 1924 |

| Driving speed with/without load | 6 / 6 km/h |