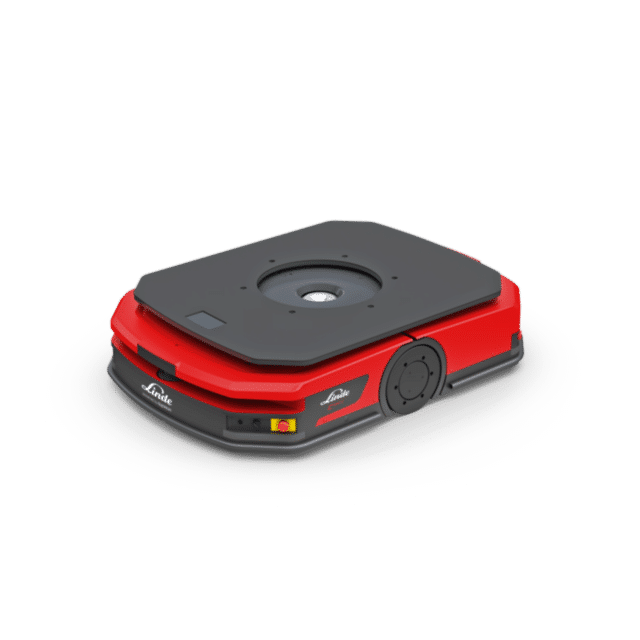

Automated vehicles Linde L-MATIC

1200 kg

1924 mm

Electric

Are you interested in this product?

Product description

The L-MATIC autonomous high lift truck from Linde Material Handling is suitable for storage or retrieval at low heights, line haulage and double-deck loading. It handles loads of up to 1,200 kilograms and lifting heights of 1.90 meters. Thanks to infrastructure-free contour navigation (SLAM), the L-MATIC can be used flexibly as a stand-alone vehicle or as part of an automated fleet. In doing so, the robotic vehicle is able to interact safely and efficiently with people, non-automated vehicles or the customer's infrastructure such as conveyor belts or packing stations. In addition, manual operation is possible at any time, for example to move the device quickly out of a danger zone in an emergency or to perform another task with it at short notice.

Features

Thanks to the extensive laser and camera-based safety equipment, the Linde L-MATIC monitors its working environment and reacts reliably if people, other vehicles or other obstacles obstruct the driving or working processes. In doing so, the system adapts the monitoring zones in real time to the travel speed and steering angle. Several emergency stop buttons as well as various acoustic and optical warning signals complete the safety features of the L-MATIC.

- All-round monitoring of the working environment

- Combined safety technology with lasers and cameras

- Audible and visual warning systems

As a single vehicle or within a fleet of automated vehicles, the L-MATIC is controlled by the supervisor software. Communication with other automated equipment, such as gates or roller conveyors, is just as easy via this as the connection to the customer's warehouse management or ERP systems. The system calculates the optimal allocation of transport orders and route guidance. Thanks to its sophisticated safety technology, the L-MATIC automatically continues the work process when people or other obstacles are no longer in the monitoring zone. To use the vehicle manually, the operator only has to grasp the control tiller.

- Interface to warehouse management and ERP systems

- Intelligent route and job control

- Precise control and monitoring of pallet movements

- Safe operation with people and non-autonomous vehicles

- Flexibly adaptable to changes

- Change to manual operation possible at any time

The L-MATIC is designed for long periods of operation. The easy accessibility of all electronic and mechanical components and the maintenance-free three-phase AC technology contribute to the high availability of the vehicle. All vehicle data relevant to maintenance of the L-MATIC can be read out on a service laptop. In addition, it is possible to set up a remote diagnostics system.

- Digital diagnostic tool

- Predictive maintenance

- Maintenance-free three-phase technology

Model overview

Model | Load capacity | Lifting height | Driving speed with/without load | Battery voltage / nominal capacity K5 |

|---|---|---|---|---|

L-MATIC | 1,2 / (2,0) (t) | 1924 (mm) | 6/6 (max. 7.2/2.9) km/h

| 24 / 375 (V)/(Ah) o. kWh |

Special equipment

Thanks to the powerful LED lights of the Linde BlueSpot™, employees are alerted to errant trucks in a pleasant but effective way: no loud noise, no startling, no risk.

Features

Thanks to the extensive laser and camera-based safety equipment, the Linde L-MATIC monitors its working environment and reacts reliably if people, other vehicles or other obstacles obstruct the driving or working processes. In doing so, the system adapts the monitoring zones in real time to the travel speed and steering angle. Several emergency stop buttons as well as various acoustic and optical warning signals complete the safety features of the L-MATIC.

- All-round monitoring of the working environment

- Combined safety technology with lasers and cameras

- Audible and visual warning systems

As a single vehicle or within a fleet of automated vehicles, the L-MATIC is controlled by the supervisor software. Communication with other automated equipment, such as gates or roller conveyors, is just as easy via this as the connection to the customer's warehouse management or ERP systems. The system calculates the optimal allocation of transport orders and route guidance. Thanks to its sophisticated safety technology, the L-MATIC automatically continues the work process when people or other obstacles are no longer in the monitoring zone. To use the vehicle manually, the operator only has to grasp the control tiller.

- Interface to warehouse management and ERP systems

- Intelligent route and job control

- Precise control and monitoring of pallet movements

- Safe operation with people and non-autonomous vehicles

- Flexibly adaptable to changes

- Change to manual operation possible at any time

The L-MATIC is designed for long periods of operation. The easy accessibility of all electronic and mechanical components and the maintenance-free three-phase AC technology contribute to the high availability of the vehicle. All vehicle data relevant to maintenance of the L-MATIC can be read out on a service laptop. In addition, it is possible to set up a remote diagnostics system.

- Digital diagnostic tool

- Predictive maintenance

- Maintenance-free three-phase technology

Technical data

- Name: Automated vehicles Linde L-MATIC

| Drive type | Electric |

|---|---|

| Load capacity (kg) | 1200 |

| Lifting height (mm) | 1924 |

| Driving speed with/without load | 6 / 6 km/h |