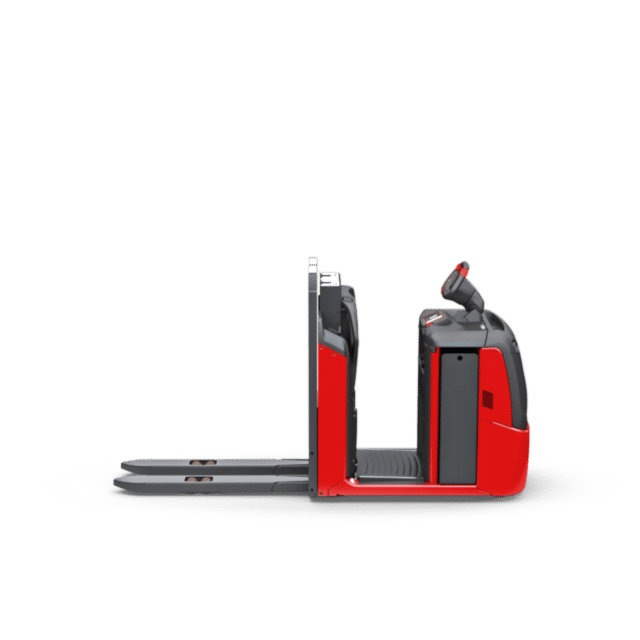

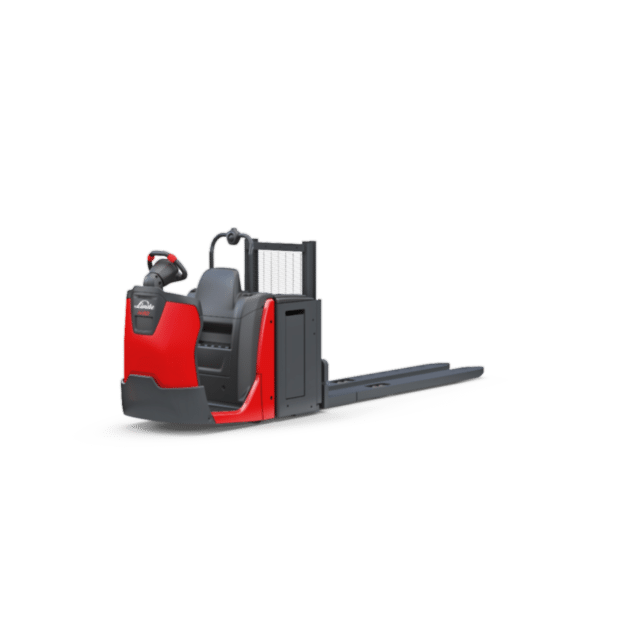

Horizontal picker N20 C L

1200 kg

700 mm

Electric

Are you interested in this product?

Product description

The N20 C L order picker from Linde Material Handling simplifies the picking process with a single pallet in several respects: Without a load, the vehicle accelerates up to 12 kilometers per hour. In curves, the speed is automatically reduced to protect the driver, goods and pedestrians. At the rack, the driver can raise the pallet to a back-friendly height and load it with up to 1.2 tons thanks to the 2.2 kW lift motor. Since the vehicle is conveniently accessible from both sides and has a pedestrian function on both sides, the operator saves unnecessary walking. Non-slip handles and easy-to-understand operation also ensure higher handling performance. For jobs on the first and second racking levels, the N20 C L is optionally equipped with a liftable load-bearing surface. A non-slip floor mat provides a firm footing at any height.

Features

Efficient order picking includes a perfected safety system. All outer edges of the robust steel chassis are rounded and lowered so that the operator cannot trap his feet. The design of the mast and lift cylinder is also engineered to minimize the risk of injury. The N20 C L's generous all-round visibility means the operator always has a good view of the forks and his surroundings. This is complemented by the optional panoramic mirror at the front of the vehicle. To avoid collisions, the order picker automatically slows its speed when going around curves and increases its braking power when carrying heavy loads. If the vehicle senses an unoccupied operator's station or the emergency button is pressed, it stops immediately. Front LEDs and Linde BlueSpot™ are available as options for even more visibility in the aisles.

- Rounded steel chassis

- Free all around view

- Speed reduction in curves

- Stop with unoccupied operator station

- Emergency button

Thanks to the free lift, the N20 C L enables ergonomic picking at operator height. Even heavy goods can thus be placed on the pallet effortlessly. Low access on both sides ensures a safe, dynamic picking cycle. At the same time, the operator can also conveniently steer his vehicle from both sides using the optional pedestrian function. Both the steering column and the backrest can be individually adjusted to suit the driver. The ergonomic steering column, automatic travel centering and a cushioned platform that compensates for unevenness in the floor ensure a pleasant driving experience.

- Back-friendly loading at operator height

- Generous access with low entry height

- Adjustable backrest and steering column

- Cushioned platform with rubber pad

The N20 C L quickly reaches its top speed of 12 kilometers per hour thanks to the 3 kW three-phase motor. With load, it accelerates to 9 km/h and brakes automatically in curves. The handling effort required to charge the battery is reduced thanks to the Linde on-board charger. With the optional lithium-ion battery, the driver can conveniently use breaks to charge the order picker in between. The adjustable Linde steering wheel offers intuitive operation. All mast and travel functions can be controlled safely even with one hand thanks to the clearly arranged controls. The operator's platform is also equipped with a storage area, a bottle holder and a paper tray.

- Powerful 3 kW three-phase motor

- Linde On-Board Charger

- Intuitive and ergonomically operated steering wheel

- Many storage options

The maintenance requirements of the N20 C L are low, with a running time of around 1,000 operating hours without a service check. The three-phase technology is even completely maintenance-free. Thanks to the CAN bus connection, the technician can read out all relevant service information quickly and easily. Access to all maintenance components is effortless. The battery cover can also be opened easily for access to the diagnostic interface.

- 1,000 operating hours without service check

- Maintenance-free three-phase technology

- CAN bus connection

- Quick access to all service components

Model overview

Model | Load capacity / load | Lifting height | Driving speed with/without load | Turning radius | Battery voltage / nominal capacity K5 |

|---|---|---|---|---|---|

N20 C L | 1,2 (t) | 700 (mm) | 9 / 12 km/h | 2007 (mm) | 24 / 420/465 (V)/(Ah) o. kWh |

Videos

Special equipment

The two semi-automated driving modes of the SA option (Semi-Automated; SA) shorten walking distances and reduce constant loading and unloading of the vehicle, as the picker automatically follows or drives ahead of the driver. This significantly increases the efficiency of horizontal picking.

The operator platform can be raised to the first and second rack levels to allow occasional picking up to 2.8 meters.

With Linde's connect: fleet management solution, it is possible, among other things, to analyze the use of the entire fleet of vehicles in order to subsequently optimize the service or utilization of the vehicle fleet.

The two headlights are located at the front and have a bright luminosity. They are waterproof and dustproof.

Vibrations caused by unevenness of the road surface are reduced by the special insulating design.

Additional protection for the driver and the load is the load protection grille, which can be adjusted depending on the height of the load.

The Linde BlueSpot™ driveway warning system increases safety during operation, as the LED spotlight makes trucks silently visible.

With Linde's innovative lithium-ion batteries, the vehicles can be recharged in a much shorter time and temporarily charged during operation.

Pushbuttons are located on both sides of the vehicle. With them, the driver operates the order picker from the outside and walks alongside at the same time.

A large mirror at the front of the vehicle provides good all-round visibility, increasing safety for the driver, cargo and pedestrians.

The lateral battery removal with roller bearing enables a quick change especially for the use in several work shifts.

Whether it's a driving error, an uneven road or improper vehicle use - a shock sensor registers vibrations. Evaluating the data via the fleet management software provides information about the cause of damage and accidents.

If the fork is fully loaded, the speed of lowering is reduced. This provides additional protection against damage to the goods.

Access control via the connect fleet management system ensures that the vehicles are only used by authorized persons. The driver must identify himself by PIN or RFID card before starting.

Features

Efficient order picking includes a perfected safety system. All outer edges of the robust steel chassis are rounded and lowered so that the operator cannot trap his feet. The design of the mast and lift cylinder is also engineered to minimize the risk of injury. The N20 C L's generous all-round visibility means the operator always has a good view of the forks and his surroundings. This is complemented by the optional panoramic mirror at the front of the vehicle. To avoid collisions, the order picker automatically slows its speed when going around curves and increases its braking power when carrying heavy loads. If the vehicle senses an unoccupied operator's station or the emergency button is pressed, it stops immediately. Front LEDs and Linde BlueSpot™ are available as options for even more visibility in the aisles.

- Rounded steel chassis

- Free all around view

- Speed reduction in curves

- Stop with unoccupied operator station

- Emergency button

Thanks to the free lift, the N20 C L enables ergonomic picking at operator height. Even heavy goods can thus be placed on the pallet effortlessly. Low access on both sides ensures a safe, dynamic picking cycle. At the same time, the operator can also conveniently steer his vehicle from both sides using the optional pedestrian function. Both the steering column and the backrest can be individually adjusted to suit the driver. The ergonomic steering column, automatic travel centering and a cushioned platform that compensates for unevenness in the floor ensure a pleasant driving experience.

- Back-friendly loading at operator height

- Generous access with low entry height

- Adjustable backrest and steering column

- Cushioned platform with rubber pad

The N20 C L quickly reaches its top speed of 12 kilometers per hour thanks to the 3 kW three-phase motor. With load, it accelerates to 9 km/h and brakes automatically in curves. The handling effort required to charge the battery is reduced thanks to the Linde on-board charger. With the optional lithium-ion battery, the driver can conveniently use breaks to charge the order picker in between. The adjustable Linde steering wheel offers intuitive operation. All mast and travel functions can be controlled safely even with one hand thanks to the clearly arranged controls. The operator's platform is also equipped with a storage area, a bottle holder and a paper tray.

- Powerful 3 kW three-phase motor

- Linde On-Board Charger

- Intuitive and ergonomically operated steering wheel

- Many storage options

The maintenance requirements of the N20 C L are low, with a running time of around 1,000 operating hours without a service check. The three-phase technology is even completely maintenance-free. Thanks to the CAN bus connection, the technician can read out all relevant service information quickly and easily. Access to all maintenance components is effortless. The battery cover can also be opened easily for access to the diagnostic interface.

- 1,000 operating hours without service check

- Maintenance-free three-phase technology

- CAN bus connection

- Quick access to all service components

Technical data

- Designation: Horizontal order picker N20 C L

| Drive type | Electric |

|---|---|

| Load capacity (kg) | 1200 |

| Lifting height (mm) | 700 |

| Driving speed with/without load | 9 / 12 km/h |

| Gripping height (mm) | 2800 |