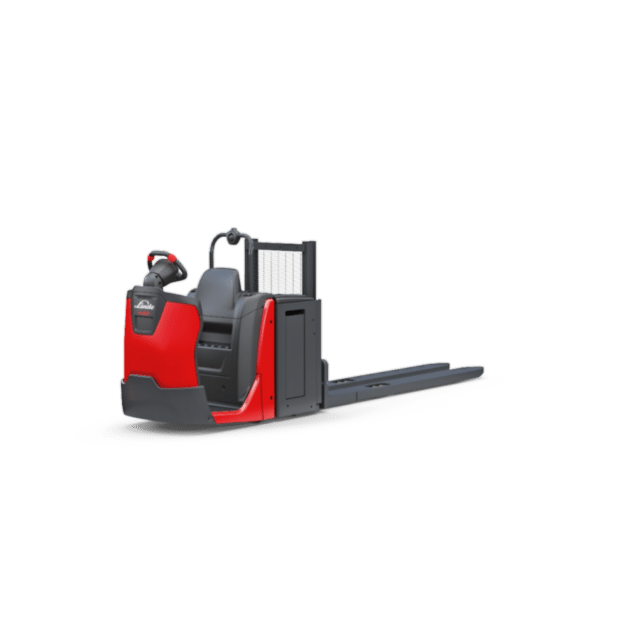

Vertical picking Linde V modular B

1000 kg

6865 mm

Electric

Are you interested in this product?

Product description

The V modular B vertical order picker from Linde Material Handling is a powerful vehicle for medium order picking heights of up to 7.8 meters and payloads of up to 1,000 kilograms. The series combines the best of the Linde order picker product family, thereby combining performance with cost efficiency. The spacious operator's cab offers the driver a comfortable workplace. In addition to the lower entry height compared to competitive trucks, the cab is decoupled from the chassis. Vibrations and impacts are only transmitted to the operator in a damped manner. As a result, the V modular B enables ergonomic and safe working and protects the operator from injury. The vertical order picker achieves a maximum lift speed of 0.4 m/s and a travel speed of up to 11 km/h, which additionally contributes to higher picking performance. Thanks to the modular vehicle concept, customers can adapt the order picker precisely to their individual requirements and, for example, choose between a 24 V and 48 V motor depending on their power needs.

Features

The mast design of the vertical order picker allows best visibility for the driver and thus contributes to safe working. The required lateral barriers from a platform height of 1.2 meters are electronically monitored and protect the operator from falling. For emergencies, there is also an emergency lowering valve that is easily accessible under the rear cover, even in narrow aisles. In addition, the service technician can adapt further configurations to local conditions. This prevents collisions with ceilings and walls. To prevent operating errors and injuries, the driver must touch the sensors on the control unit with both hands and activate the dead man's switch in the footwell. Only then can the vehicle be moved. In the narrow aisle, the personal protection system with two scanners in the load and drive directions protects the operator and actively intervenes in the driving behavior.

- Very good mast visibility

- Electrically monitored side barriers

- Three-point control

- Emergency lowering valve under the rear cover

- Travel, lift and lowering stops can be preset

Order picking is one of the most physically demanding tasks in the warehouse. The V modular B vertical order picker supports the operator with numerous design measures: In the spacious cabin, the operator can work in a relaxed manner. Depending on requirements, many storage areas and equipment options are available. A low parapet makes it easier to pick up and place goods. The patented ergo roller allows the operator to lean back and relaxes his muscles. Optional side barriers are available that tilt slightly outward, allowing the operator to reach deeper into the rack. During travel, the platform and a soft mat cushion vibrations, preventing operator fatigue. When picking, he stands securely on the solid surface at the edge of the cabin floor.

- Ergonomic control panel

- Many storage areas and equipment variants

- Spacious cabin with rounded contours

- Low parapet

- Suspension cab with anti-vibration mat

Thanks to the electric steering, the vehicle can be maneuvered easily, quickly and precisely. The high lifting and travel speeds additionally contribute to high handling rates. At the same time, the three-phase AC motors of the Linde vertical order pickers are characterized by low energy consumption and a high residual load capacity at lifting heights of up to 7.8 meters.

- Precise steering for fast maneuvering

- High residual load capacity

- Energy saving

- High lifting and travel speeds

The Linde vertical order picker is designed to be service-friendly all around: The central components are easily accessible behind a panel. The travel and lift motors are encapsulated and thus protected from dust and dirt. This means fewer downtimes for repairs and maintenance. Service technicians can read out and check all central data via the CAN bus interface.

- Easily accessible service components

- Maintenance-free travel and hoist motors

- Vehicle data can be read out via CAN bus connection

Model overview

Model | Load capacity | Lifting height | Driving speed with/without load | Turning radius | Working aisle width for pallet 800 x 1200 lengthwise |

|---|---|---|---|---|---|

V modular B 24V standard mast | 1,0 (t) | 4550 (mm) | 9 / 9 km/h | 1585 | -

|

V modular B 48V standard mast | 1,0 (t) | 5000 (mm) | 10 / 10 km/h | 1958 (mm) | 1820 (mm)

|

V modular B 48V standard mast | 1,0 (t) | 6000 (mm) | 10 / 10 km/h | 1958 (mm) | 1820 (mm)

|

Special equipment

The control panel can optionally be mounted on load side or on load and mast side - the operating logic is maintained.

For example, a terminal, scanner, clipboard, desk pad or individual attachments can be fastened. The carriers can be attached to the left and right of the mast as well as on the load side and on the overhead guard.

The loading area is secured with a protective cage. The operator can therefore enter it safely and pick from here.

![]()

The Linde BlueSpot™ increases safety during operation, as the LED spotlight makes trucks silently visible.

How and by whom are the individual trucks used? What does the consumption data of the vehicles look like and is each one roadworthy? In the interaction of software and hardware, connect: provides the relevant answers.

The system ensures faster handling and more safety. In the basic LSC Standard version, the remaining load capacity for the respective lift height is displayed to the operator. Extended LSC versions adapt additional lift and/or travel speed to the transported load weight.

When the driver leans against the barrier, it folds outward ten centimeters. This gives him better access to the rack and makes picking easier.

Large mirrors in both directions as well as work lights support the operator in daily work. As an option, fans are available to cool the operator under the roof in hot conditions at high lift heights.

In the narrow aisle, the personal protection system with two scanners in the load and drive direction protects the operator and actively intervenes in the travel behavior.

Features

The mast design of the vertical order picker allows best visibility for the driver and thus contributes to safe working. The required lateral barriers from a platform height of 1.2 meters are electronically monitored and protect the operator from falling. For emergencies, there is also an emergency lowering valve that is easily accessible under the rear cover, even in narrow aisles. In addition, the service technician can adapt further configurations to local conditions. This prevents collisions with ceilings and walls. To prevent operating errors and injuries, the driver must touch the sensors on the control unit with both hands and activate the dead man's switch in the footwell. Only then can the vehicle be moved. In the narrow aisle, the personal protection system with two scanners in the load and drive directions protects the operator and actively intervenes in the driving behavior.

- Very good mast visibility

- Electrically monitored side barriers

- Three-point control

- Emergency lowering valve under the rear cover

- Travel, lift and lowering stops can be preset

Order picking is one of the most physically demanding tasks in the warehouse. The V modular B vertical order picker supports the operator with numerous design measures: In the spacious cabin, the operator can work in a relaxed manner. Depending on requirements, many storage areas and equipment options are available. A low parapet makes it easier to pick up and place goods. The patented ergo roller allows the operator to lean back and relaxes his muscles. Optional side barriers are available that tilt slightly outward, allowing the operator to reach deeper into the rack. During travel, the platform and a soft mat cushion vibrations, preventing operator fatigue. When picking, he stands securely on the solid surface at the edge of the cabin floor.

- Ergonomic control panel

- Many storage areas and equipment variants

- Spacious cabin with rounded contours

- Low parapet

- Suspension cab with anti-vibration mat

Thanks to the electric steering, the vehicle can be maneuvered easily, quickly and precisely. The high lifting and travel speeds additionally contribute to high handling rates. At the same time, the three-phase AC motors of the Linde vertical order pickers are characterized by low energy consumption and a high residual load capacity at lifting heights of up to 7.8 meters.

- Precise steering for fast maneuvering

- High residual load capacity

- Energy saving

- High lifting and travel speeds

The Linde vertical order picker is designed to be service-friendly all around: The central components are easily accessible behind a panel. The travel and lift motors are encapsulated and thus protected from dust and dirt. This means fewer downtimes for repairs and maintenance. Service technicians can read out and check all central data via the CAN bus interface.

- Easily accessible service components

- Maintenance-free travel and hoist motors

- Vehicle data can be read out via CAN bus connection

Technical data

- Designation: Vertical picking Linde V modular B

| Drive type | Electric |

|---|---|

| Load capacity (kg) | 1000 |

| Lifting height (mm) | 6865 |

| Gripping height (mm) | 7833 |

| Driving speed with/without load | 10 / 10 km/h |