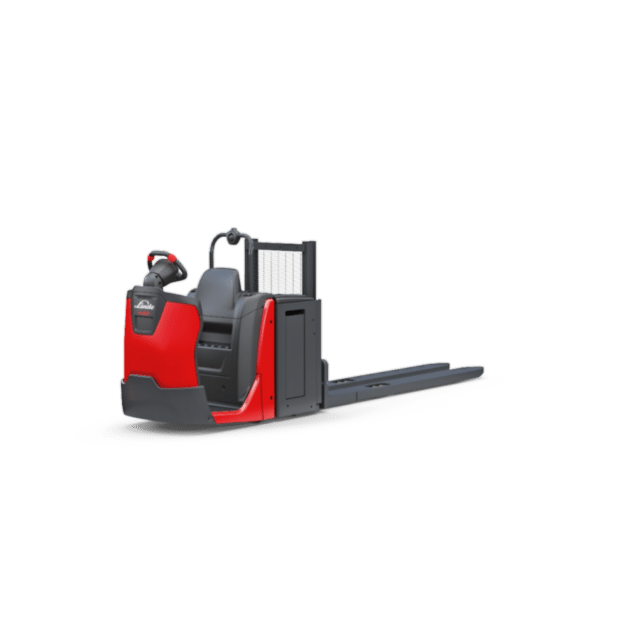

Horizontal Picker N20 C LoL

2000 kg

800 mm

Electric

Are you interested in this product?

Product description

The N20 C LoL order picker enables ergonomic filling of two pallets in just one picking cycle thanks to long load arms and the additional, liftable fork. The operator first starts with a pallet at the desired height, while a second one is optionally attached vertically to the back of the fork with a special safety device. Once the first pallet is filled, it is lowered onto the load arms and transported along in front of the fork. The second pallet can then be effortlessly transferred to the forks and also loaded at a height that is easy on the back. The N20 C LoL thus offers fast and ergonomic order picking. In the process, the mast can be controlled to the right and left of the backrest respectively and the vehicle moved on to the next rack segment. As an option, the operator's platform can be raised so that picking can occasionally take place on the second shelf level. The initial lift also ensures easy transport over ramps and uneven surfaces.

Features

Both in curves and when the forks are lowered, the vehicle automatically adjusts its speed, thereby increasing the safety of the driver and the load. In addition, the N20 C LoL has three different braking systems. These boost braking power in proportion to the weight of the load and stop the vehicle as soon as the driver's platform is unoccupied. In addition, the vehicle brakes automatically when the operator releases the drive switch. Further risk minimization is provided by the flattened contours and rounded edges on the vehicle's operator platform. To protect the feet from injury when operating the mast and vehicle via the buttons on either side of the backrest, the N20 C LoL is equipped with guards on both sides of the chassis with this option.

- Automatic speed adjustment in curves

- Low speed with lowered fork

- Three different braking systems

- Rounded chassis

The N20 C LoL order picker offers a high level of operator friendliness: Low and wide access from both sides of the vehicle enables flexible and speedy order picking to both sides of the rack. Accordingly, the mast control and the controls for travel and initial lift are also located on both sides of the backrest. After filling the first pallet, the operator can conveniently transfer the second pallet, optionally carried on the fork back, to a back-friendly height without interruption and load it as well. Both the Linde steering wheel and the backrest are adjustable and can be individually adapted to the operator. The cushioned platform reduces vibrations in the operator's platform caused by driving on uneven ground.

- Spacious access on both sides

- Low entry height

- Mast and pedestrian control on both sides

- Steering wheel and backrest height adjustable

- Reduction of vibrations

Powered by a 3 kW three-phase motor, the N20 C LoL order picker accelerates briskly to 12 kilometers per hour - fully loaded, it reaches 9 km/h. The Linde on-board charger enables easy battery handling. Through short and fast intermediate charging, the optional lithium-ion technology also increases the availability of the vehicles. The Linde steering wheel with its sleek design, which can be individually adapted to the driver, ensures intuitive and sensitive control. The controls for all travel and mast functions are integrated into the steering wheel and clearly arranged. This allows the N20 C LoL to be maneuvered easily and quickly even in tight spaces. The operator's workstation also features storage areas, bottle holders and a knee guard that can be used as a paper tray.

- Powerful 3 kW three-phase motor

- Linde steering wheel with intuitive controls

- Linde on-board charger

- Lithium-ion battery optional

- Various shelves and compartments

The three-phase technology is completely maintenance-free and there is no need to readjust the brakes. A service check is only necessary after around 1,000 operating hours. All vehicle data can be read out quickly and easily using the CAN bus connection. The technician can easily reach all service components and open the battery cover.

- Maintenance-free three-phase technology

- No readjustment of the brakes

- 1,000 operating hours without service check

- CAN bus connection

- Easily accessible service components

Model overview

Model | Load capacity / load | Lifting height | Driving speed with/without load | Turning radius | Battery voltage / nominal capacity K5 |

|---|---|---|---|---|---|

N20 C LoL | 1,0 / 2,0 (t) | 800 (mm) | 9 / 12 km/h | 3271 / 3399 (mm) | 24 / 420/465 (V)/(Ah) o. kWh |

Videos

Special equipment

The two semi-automated driving modes of the SA option (Semi-Automated; SA) shorten walking distances and reduce constant loading and unloading of the vehicle, as the picker automatically follows or drives ahead of the driver. This significantly increases the efficiency of horizontal picking.

The operator platform can be raised up to 2.80 meters picking height for occasional picking at the first and second rack levels.

With Linde's connect: fleet management solution, it is possible, among other things, to analyze the use of the entire fleet of vehicles in order to subsequently optimize the service or utilization of the vehicle fleet.

The two headlights are located at the front and have a bright luminosity. They are waterproof and dustproof.

The bracket is mounted on the load guard and allows safe vertical transport of a second pallet while the first pallet is being filled by the operator.

Vibrations caused by unevenness of the road surface are reduced by the special insulating design.

Additional protection for the driver and the load is the load protection grille, which can be adjusted depending on the height of the load.

The Linde BlueSpot™ driveway warning system increases safety during operation, as the LED spotlight makes trucks silently visible.

With Linde's innovative lithium-ion batteries, the vehicles can be recharged in a much shorter time and temporarily charged during operation. This increases the availability of the equipment.

Pushbuttons are located on the lift mast on both sides of the vehicle. With them, the driver operates the order picker from the outside and walks alongside at the same time.

A large mirror at the front of the vehicle provides good all-round visibility, increasing safety for the driver, cargo and pedestrians.

The lateral battery removal with roller bearing enables a quick change especially for the use in several work shifts.

Whether driving error, uneven ground or improper vehicle use - a shock sensor registers vibrations. Evaluating the data via the fleet management software provides information about the cause of damage and accidents.

If the fork is fully loaded, the speed of lowering is reduced. This provides additional protection against damage to the goods.

Access control via the connect fleet management system ensures that the vehicles are only used by authorized persons. The driver must identify himself by PIN or RFID card before starting.

Features

Both in curves and when the forks are lowered, the vehicle automatically adjusts its speed, thereby increasing the safety of the driver and the load. In addition, the N20 C LoL has three different braking systems. These boost braking power in proportion to the weight of the load and stop the vehicle as soon as the driver's platform is unoccupied. In addition, the vehicle brakes automatically when the operator releases the drive switch. Further risk minimization is provided by the flattened contours and rounded edges on the vehicle's operator platform. To protect the feet from injury when operating the mast and vehicle via the buttons on either side of the backrest, the N20 C LoL is equipped with guards on both sides of the chassis with this option.

- Automatic speed adjustment in curves

- Low speed with lowered fork

- Three different braking systems

- Rounded chassis

The N20 C LoL order picker offers a high level of operator friendliness: Low and wide access from both sides of the vehicle enables flexible and speedy order picking to both sides of the rack. Accordingly, the mast control and the controls for travel and initial lift are also located on both sides of the backrest. After filling the first pallet, the operator can conveniently transfer the second pallet, optionally carried on the fork back, to a back-friendly height without interruption and load it as well. Both the Linde steering wheel and the backrest are adjustable and can be individually adapted to the operator. The cushioned platform reduces vibrations in the operator's platform caused by driving on uneven ground.

- Spacious access on both sides

- Low entry height

- Mast and pedestrian control on both sides

- Steering wheel and backrest height adjustable

- Reduction of vibrations

Powered by a 3 kW three-phase motor, the N20 C LoL order picker accelerates briskly to 12 kilometers per hour - fully loaded, it reaches 9 km/h. The Linde on-board charger enables easy battery handling. Through short and fast intermediate charging, the optional lithium-ion technology also increases the availability of the vehicles. The Linde steering wheel with its sleek design, which can be individually adapted to the driver, ensures intuitive and sensitive control. The controls for all travel and mast functions are integrated into the steering wheel and clearly arranged. This allows the N20 C LoL to be maneuvered easily and quickly even in tight spaces. The operator's workstation also features storage areas, bottle holders and a knee guard that can be used as a paper tray.

- Powerful 3 kW three-phase motor

- Linde steering wheel with intuitive controls

- Linde on-board charger

- Lithium-ion battery optional

- Various shelves and compartments

The three-phase technology is completely maintenance-free and there is no need to readjust the brakes. A service check is only necessary after around 1,000 operating hours. All vehicle data can be read out quickly and easily using the CAN bus connection. The technician can easily reach all service components and open the battery cover.

- Maintenance-free three-phase technology

- No readjustment of the brakes

- 1,000 operating hours without service check

- CAN bus connection

- Easily accessible service components

Technical data

- Designation: Horizontal order picker N20 C LoL

| Drive type | Electric |

|---|---|

| Load capacity (kg) | 2000 |

| Lifting height (mm) | 800 |

| Driving speed with/without load | 9 / 12 km/h |

| Gripping height (mm) | 2800 |